Automate Your Benchwork with Ease

- Assay Development and Design of Experiment (DoE)

- Enzyme-Linked Immunosorbent Assays (ELISA)

- PCR Workflows

- Cell Culture and Bead-Based Assays

- NGS Library Preparation

- Nucleic Acid and Protein Extraction

- Screening Assays (e.g., COVID)

- Lipid Nanoparticle (LNP) Formulation Screening

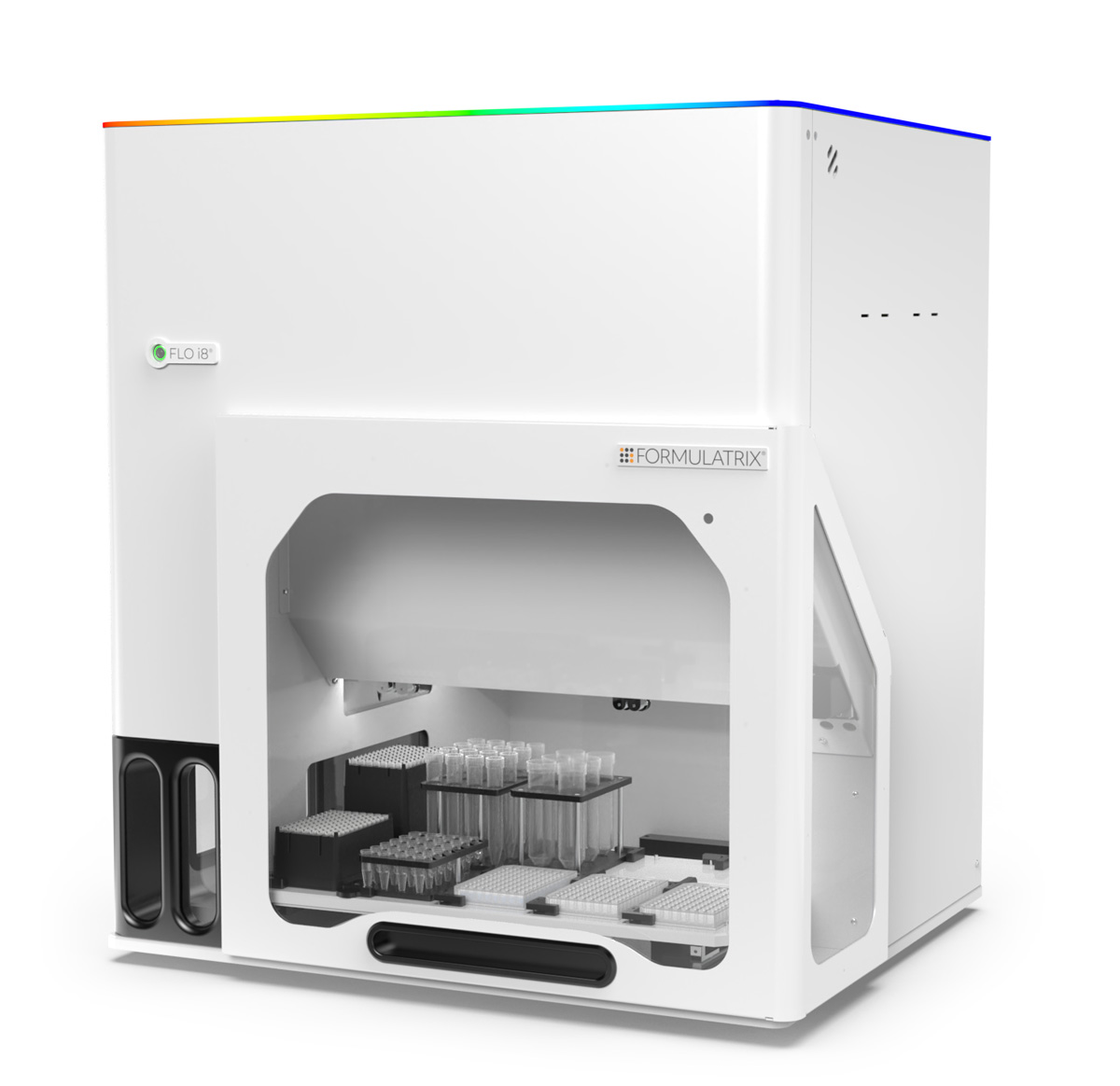

The FLO i8® Liquid Handler is ideal for optimizing your protocols and bench work, allowing you to focus on the research, the science, and new innovations and breakthroughs.

Intuitive software, flexible hardware, and intelligent pipetting guarantees precise liquid transfers with no need to specify:

- Source volumes

- Labware geometries

- Liquid properties

Benefits

Incredibly Easy Software – Designing your protocol has never been easier

Flexible – Simplify all of your tube or plate-based labwork using the variable spanning channels and pipetting range of 0.5 to 1000 μL

Precise – Reduce variability in your workflows and increase your traceability and confidence in your experiments

Intelligent – Automatically sense labware, detect and track liquid levels, and optimize liquid transfers in real time with no prior input of liquid properties needed

Automation-Friendly – The FLO i8's software offers an open API for seamless integration, as demonstrated by the comprehensive API list showcasing how effortlessly integratable it is

Overview of the FLO i8

A Liquid Handler That Optimizes Pipetting So You Don't Have To

Our liquid handler with 8 independently spanning channels simplifies experimental design, setup, and execution. The hardware offers the flexibility to handle any labware or protocol you throw at it, and the intuitive software makes it easy to define your workflow. With real-time progress monitoring, intelligent channels and tips, and pipetting optimization on the fly, the FLO i8 will be the lab partner you can't live without.

Key Features

- 8 fully independent channels

- Wide Volume Range (0.5 - 1000 µL)

- Intuitive Software

- Automatic Liquid Class optimization

- Patented Next-Level Tips® technology

- Intelligent liquid level detection and tracking

- Precise and accurate transfers

- Smooth deck motion

Design Your Experiment, The FLO i8 Handles the Rest…

FLO i8 Liquid Handler breaks the mold of traditional liquid handlers. By designing a system that automatically optimizes pipetting and has the ability to sense the world surrounding the pipette tip, we have reduced the effort to create a protocol in the system to just that: design your protocol. We have developed a software interface that is incredibly easy to use, and has the dynamic range to handle both the simplest liquid transfers to the most complex workflows you still perform by hand. By using the FLO i8, you increase the fidelity of your experiments while reducing the days spent at the bench. With the FLO i8 Liquid Handler, FORMULATRIX aims to promote scientific discovery through enabling efficient and reproducible research.

Automated Liquid Transfer Optimization

With time-consuming liquid class optimization, liquid handlers have been transferring liquids of varying viscosities and surface tensions for years. Finally, FORMULATRIX has developed a liquid handler that optimizes liquid transfers automatically.

Integrated pressure sensors in each pipetting channel independently monitor the aspiration and dispensing of samples and reagents, and react in real time to reproducibly pipette liquids of any viscosity and surface tension. The algorithms embedded in the FLO i8 Liquid Handler uses this input to dynamically adjust pipetting parameters to achieve reproducible sample preparation.

Pipetting accuracy and precision are guaranteed without user adjustment of pipetting flow rate, equilibration time, or offsets for various liquid classes.

Dynamic Liquid Level Detection and Tracking

The FLO i8 Liquid Handler takes liquid level detection and tracking to the next level with sensors that enable dynamic liquid level tracking without prior definition of labware well profiles. Scientists can focus on their experiments instead of programming complex parameters.

Protocols can be designed quickly and easily, making the FLO i8 a viable replacement for manual pipettes as the tool of choice for simple liquid handling tasks like a serial dilution of 1-8 samples.

"Software was surprisingly intuitive and quickly adopted in my group."

Huy Nguyen

Scientist at Genentech

Never Have to Program the Dimensions of Your Wells Again

Before dispensing into an empty plate, tip touch sensors detect the bottom or sides of the well in order to enable researchers to use any SBS footprint microliter plate without programming the dimensions of the labware.

The pipette touch sensors also facilitate best-in-class error management and safety by detecting collisions with obstructions and halting motion before causing damage. Researchers can simply remove the obstruction, and the FLO i8 will continue from where it left off.

The FLO i8 touch sensor can detect a collision with only 30 grams of force, and the position of the pipette tip is repeatable to within 50 microns.

Set Up Liquid Transfers in Seconds

The FLO i8 features a user-friendly interface that allows you to select your labware, source, destination wells, and transfer pattern with just a few clicks. The system then automatically locates the available tips in the tip caddy and uses its 8 independent spanning channels to complete the transfer with high precision and accuracy (CV <5% at 1 µL).

Efficient Serial Dilution for Your Assays

It is quick and intuitive to set up serial dilutions on the FLO i8. The user selects the samples to dilute, the number of dilution points, the dilution factor, and the sample volume. The system calculates the necessary volume of diluent and dispenses it into each well. The samples are then transferred to the first column or row, mixed, and then transferred to the next column or row. Various customizations are available to maximize mixing efficiency, such as the number of mixing cycles, flow rate, and the position of the tip while aspirating or dispensing.

Simplify Setup with Vision-based Deck Scanning

The FLO i8 Liquid Handler is equipped with a vision system enabling Automatic Tip Detection and Labware Presence Detection capabilities. Prior to each run, the camera scans the deck to check for the presence of labware in each deck position, and to verify that there are sufficient tips for the protocol. The system determines the size, number, and location of tips on the deck, informing the user if there is an error. By verifying the deck layout and tips, this capability simplified setup and reduces risk of user error. With the FLO i8's vision capabilities, users can increase their productivity and focus on other important aspects of their work.

When Sterility Matters

The FLO i8 can be equipped with an optional HEPA filter and sterile tips to reduce the risk of foreign contamination during liquid handling. The HEPA module helps provide a clean work environment by creating positive pressure within the enclosure, minimizing the chance of external contaminants interfering with experiments. The module contains a replaceable HEPA 14 filter to remove contaminants like viruses, bacteria, fungi, and other microorganisms from the air.

The system’s sterile pipette tips have undergone sterilization by ethylene oxide and are certified to be free of microorganism contamination. This makes them suitable for applications that demand aseptic conditions, such as cell culture and other sensitive assays.