Bioconjugates are macromolecular complexes composed of a biomolecule (e.g. protein, nucleic acid) bonded covalently to a functional moiety (e.g. drug, chromophore) which enhances their physico-chemical properties and functionality. They have broad applications in areas like targeted drug delivery, diagnostics, and therapeutics.

The types of bioconjugates vary widely depending on the specific biomolecules involved and the desired properties of the final product. Common examples of bioconjugates include antibody-drug conjugates or ADCs (formed by linking a therapeutic drug to an antibody for targeted delivery), fluorescently labeled proteins (for imaging and studying protein localization and dynamics), and nanoparticle-biomolecule conjugates (for drug delivery, imaging, and biosensing).

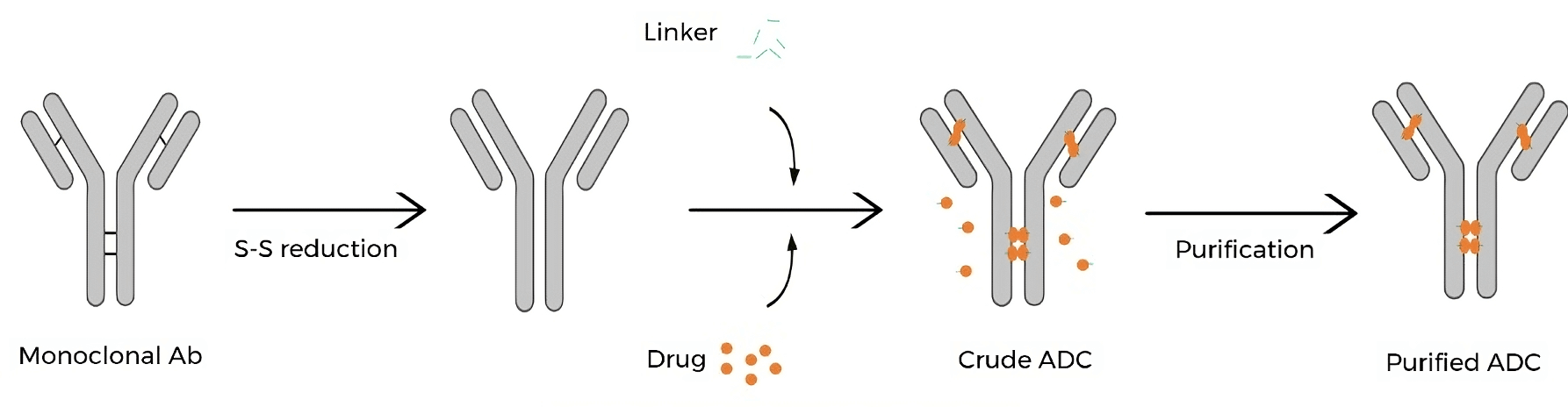

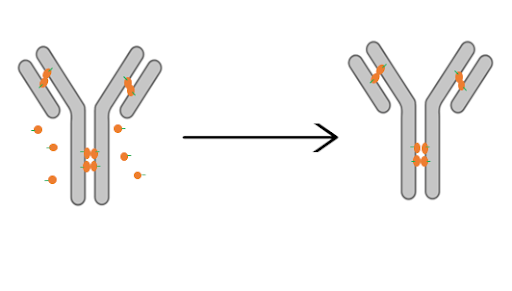

A typical biosynthetic workflow of bioconjugates such as ADCs includes synthesis, purification (bioconjugate cleanup) and formulation. Bioconjugate cleanup is integral to the production workflow which involves the removal of unbound molecules and other impurities from the reaction mixture. This is crucial, as the presence of unconjugated material in the final sample can interfere with the desired function, leading to non-specific results or even toxicity, if intended for therapeutics. Likewise, final formulation of the bioconjugates at appropriate concentration and in a specific buffer is necessary to ensure their structural integrity and effectiveness for downstream applications. Besides cleanup efficacy and gentleness, another crucial factor to be considered is the processing time. Faster purification methods are often preferred, especially while processing large volumes for time-sensitive applications. Additionally, the chosen method should not be limited by specific volume and should be easily adapted to scale up for larger volumes.

ADC's synthesis & purification

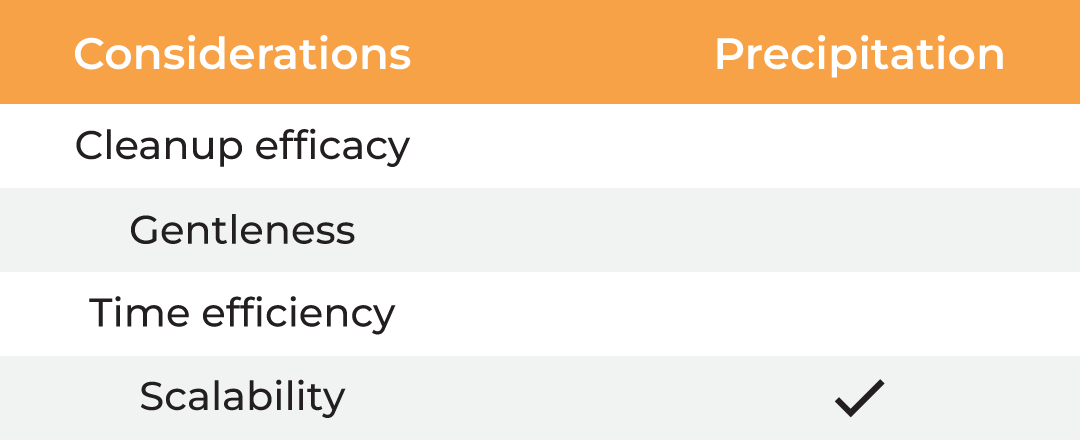

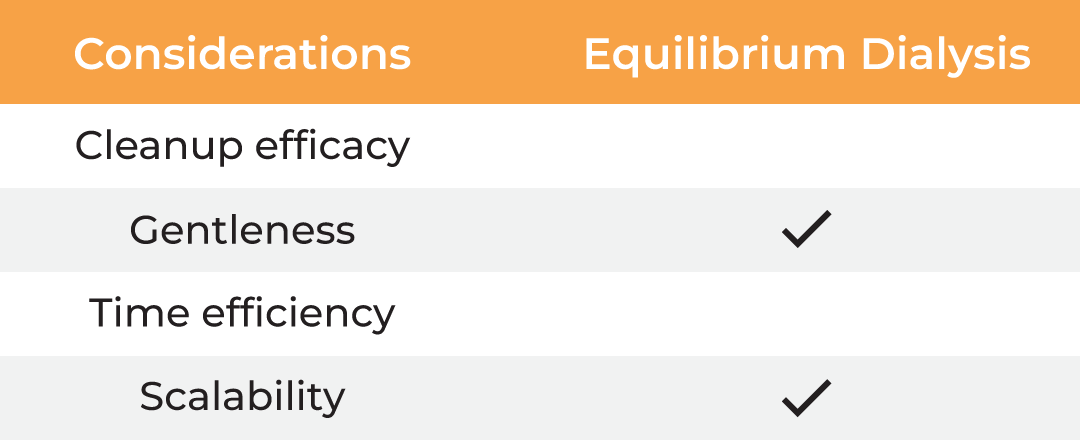

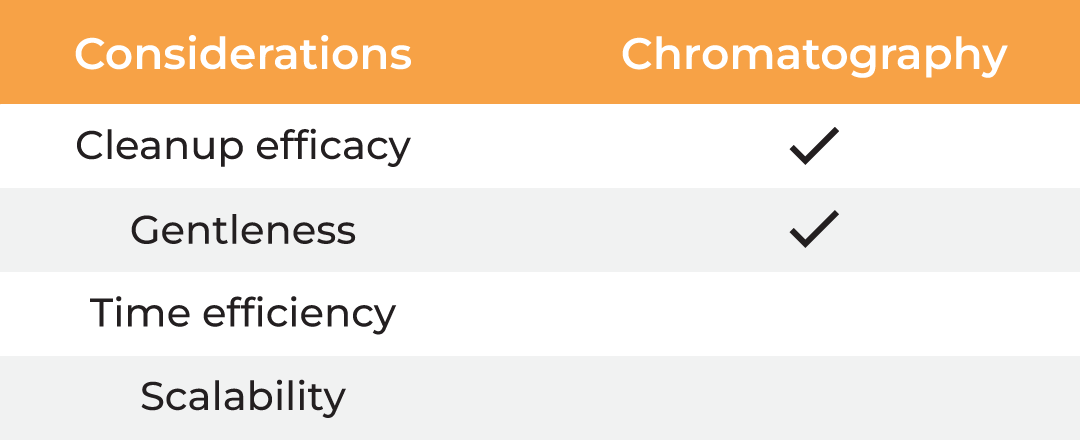

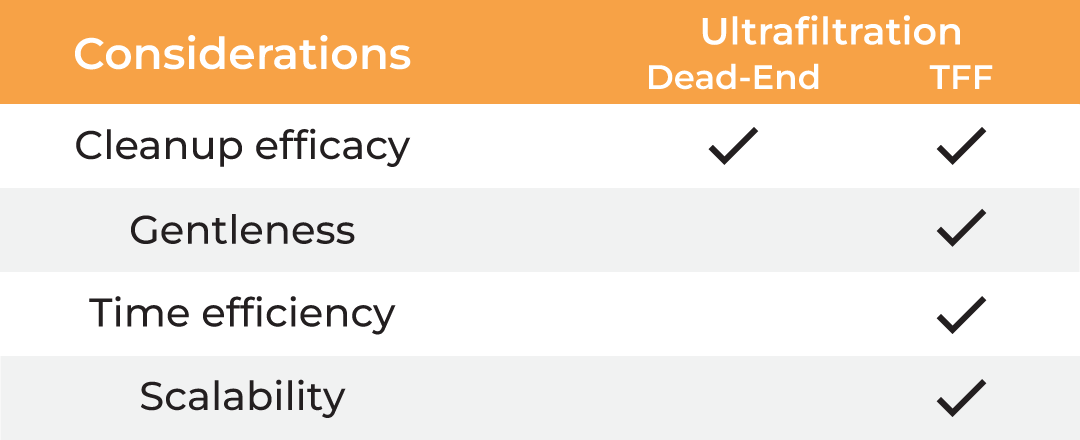

The table below shows the comparison of common techniques used for bioconjugate cleanup. It is evident that ultrafiltration addresses all the considerations of bioconjugate cleanup compared to the conventional methods. However, ultrafiltration using dead-end devices is limited by low filtration rates as well as lack of scalability, and is often accompanied by sample loss. Moreover, it is fairly a hands-on method. In contrast, ultrafiltration in the form of tangential flow filtration (TFF) offers higher filtration rates and scalability. Additionally, the TFF has the advantage of simultaneous purification and formulation of bioconjugates. However, conventional TFF systems are large, with high hold-up volumes, making them unsuitable for lab scale applications.

| Considerations | Precipitation | Equilibrium Dialysis | Chromatography |

Ultrafiltration Dead-End TFF |

|---|---|---|---|---|

| Cleanup efficacy | ||||

| Gentleness | ||||

| Time efficiency | ||||

| Scalability |

Table: Comparison of techniques used for bioconjugate cleanup

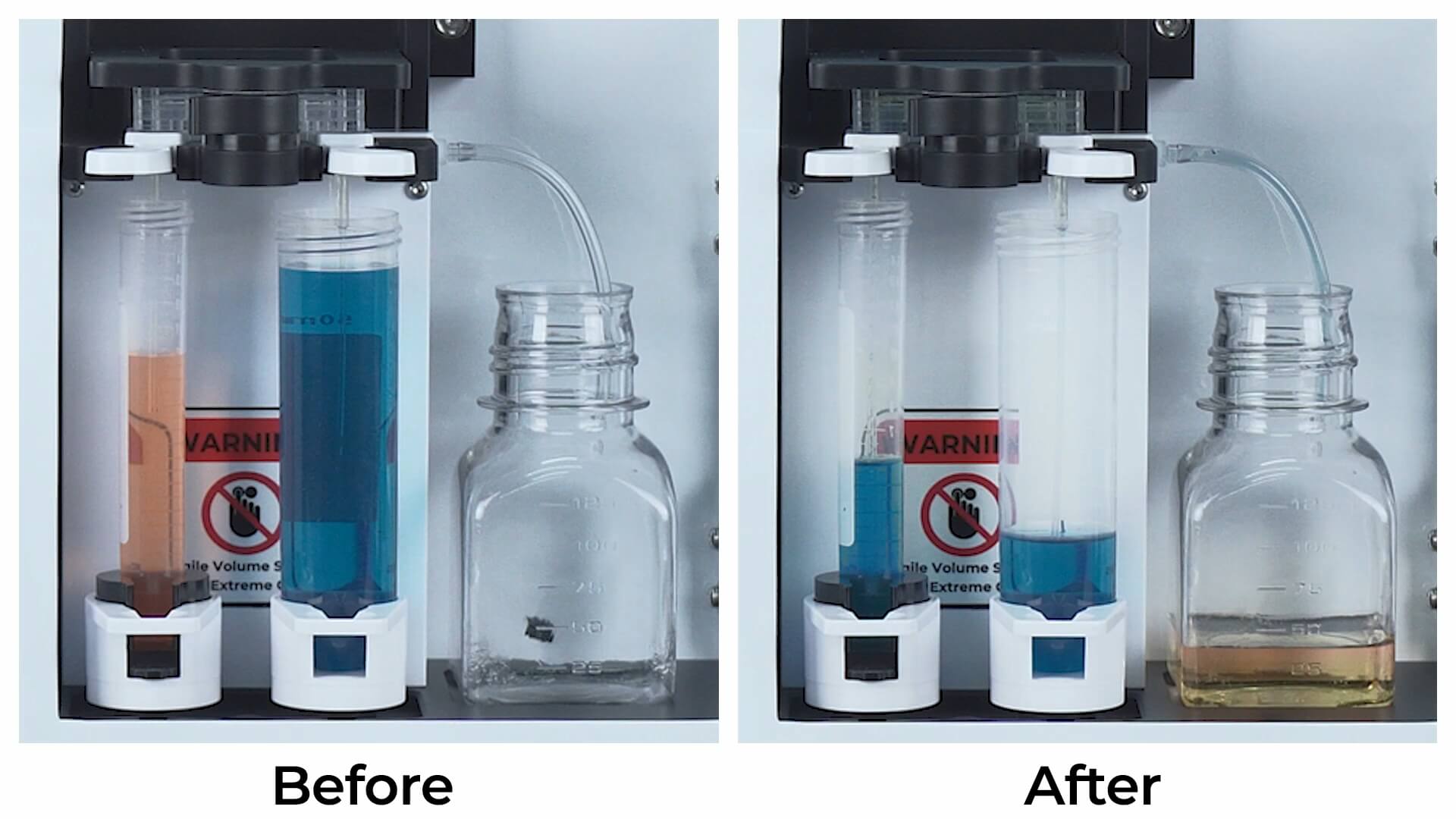

Bioconjugate Cleanup Using the µPulse - TFF System

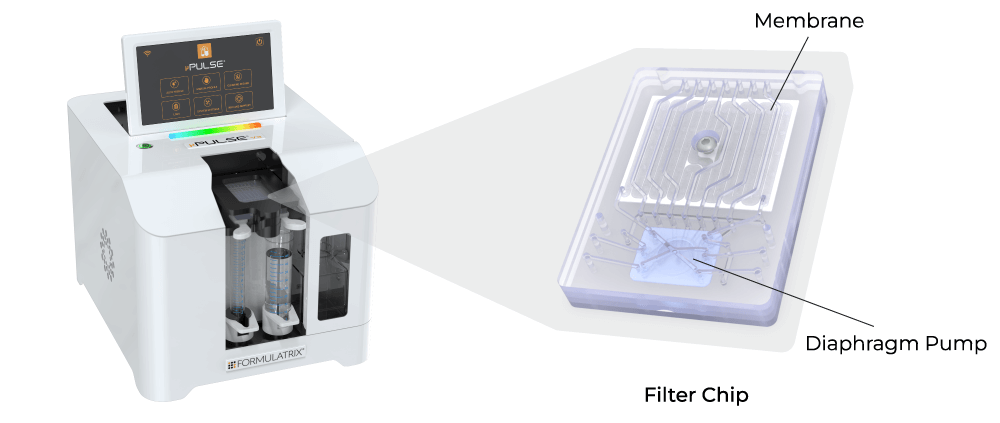

The µPulse® is an automated and miniaturized TFF system, explicitly designed for lab scale applications. It is well suited for the purification of a variety of bioconjugates including ADCs, oligonucleotide antibody complexes, fluorescent labels, peptide carrier, and biotinylated conjugates.

The entire fluid path is miniaturized on the filter chip by combining microfluidic pumping technology with TFF. This has reduced the hold-up volume to just 0.65 mL, ensuring maximum hold-up recovery. The filter chips are available with modified polyethersulfone (mPES) and regenerated cellulose (RC) membranes that exhibit low fouling characteristics and are compatible with a variety of sample types.

The µPulse offers customizable parameters such as operating pressures to make the process gentle, ensuring homogenous conjugation ratio. Furthermore, it processes samples 4x faster compared to the dead-end centrifugal units, and in a walk-away approach.

High-throughput Bioconjugate Cleanup with the aµtoPulse - TFF System

The aµtoPulse® is a fully automated, high-throughput TFF system with the world’s lowest hold-up volume of just 250 µL. It processes up to 54 samples per run, with up to 4 samples in parallel. Designed for flexibility, it handles starting volumes between 0.5 mL to 100 mL and can concentrate samples down to 250 µL with ±25 µL precision. The system supports up to four external buffer inputs or on-deck conical tubes, enabling automated multi-buffer diafiltration.

The advanced chip design with dual pumps delivers permeate flow rates up to 1.7x faster than the µPulse while minimizing shear, particularly important for delicate conjugates like ADCs and oligo-protein complexes. The chips are available with mPES (5–300 kDa) and RC (5–100 kDa) membranes, ensuring compatibility with a wide range of samples.

Each station offers independent regulation and monitoring of transmembrane pressure (0–32 psi), giving users full control over process gentleness and efficiency. The intuitive, browser-based software enables remote protocol setup, monitoring, and control, with secure data management compliant with 21 CFR Part 11 for GMP environments.

Webinars

Experience the single-step and scalable purification of ADCs and other macromolecules modified with small molecules using the µPulse.

Explore a novel, automated and walk away approach for sample concentration and buffer exchange at lab scale using the µPulse - a miniaturized TFF system

FAQs

How does TFF improve recovery in antibody-drug conjugate (ADC) workflows?

Tangential flow filtration (TFF) improves recovery in antibody-drug conjugate (ADC) workflows by enabling gentle, controlled concentration and buffer exchange while minimizing shear and membrane fouling. Unlike dead-end filtration, TFF’s tangential flow continuously sweeps the membrane, reducing aggregation and adsorption of sensitive ADC molecules. Systems like µPulse and aµtoPulse further enhance recovery with low hold-up volumes and precise transmembrane pressure control, ensuring that even small or viscous samples are processed efficiently with minimal product loss, preserving both antibody structure and conjugated payload integrity.

What are typical yields when using TFF for bioconjugates?

Typical yields when using TFF for bioconjugates often reach 95–100% for low- to moderate-volume samples. Systems like µPulse and aµtoPulse, with their low hold-up volumes and precise transmembrane pressure control, help maximize recovery by minimizing product loss due to membrane adsorption, dead volume, or fouling, ensuring consistent and reproducible results even for sensitive or viscous conjugates.

How does TFF impact the drug-antibody ratio (DAR) and homogeneity in ADC final products?

TFF helps maintain the drug-antibody ratio (DAR) and product homogeneity in ADC final formulations by providing gentle, controlled concentration and buffer exchange. Its tangential flow minimizes shear and reduces aggregation or adsorption that can alter the DAR. Automated low hold-up systems like µPulse and aµtoPulse ensure consistent recovery and reproducible processing, enabling removal of unreacted drug or small-molecule contaminants without affecting the conjugated antibody, ultimately preserving both the intended DAR and product uniformity.