Focus on Your Research as the Cell Automation Suite Grows Your Cells

The system handles the manual labor of feeding, splitting, and handling your cells.

- 24/7 operation maintaining and handling adherent cell culture plates allowing scientists to spend their valuable time on research

- Replace flasks with plates for easy expansion and handling of multiple cell lines

- Store and handle up to 400 SBS-sized plates; your choice of plate density from single-well up to 384-well plates

- Easily define cell maintenance and assay plate orders with our cell-application specific scheduling software

- Web-based software allows access anywhere, to check on the progress of your cells; email and text notifications are available if any problems are found

Maintain Several Cell Lines with Intelligent Scheduling

Simplified protocol programming and resource management

The system’s scheduler allows multiple groups and users to run protocols for different cell lines simultaneously. Protocols are executed in parallel, maximizing instrument usage. The scheduling automatically interweaves methods and requires no scripting from end users.

Versatile for a Broad Range of Scientific Workflows

Stem Cell

Differentiation

Automate week and month long protocols with thoughtful management of expensive reagents

Cell Line

Development

Pick colonies and propagate forward

from 384- and 96-well plates

Routine Maintenance and

Expansion

Continuously feed, image, and passage cell lines

with extensive data record keeping

Multi-well Plating

for HT Screens

Dispense cells into 384- and 96-well plates at user defined cell number

Permeability Assays with

Transwell Plates

Feed and culture cells in transwell plates

for your permeability assays

Immunology Studies with

PBMCs

Differentiate and mature blood cells for

immunological assays

Save Time and Reagents with Smart Liquid Handling

Have users with different media and reagent needs?

The system can support over 50 different media solutions and reagents simultaneously. Dispensing is performed within a sterile refrigeration unit to eliminate long tubing and priming of expensive reagents. Dispensed media is then warmed prior to use with your cell culture plates. User intervention is minimized by having the capacity to store up to 3 weeks' worth of media with premixing on demand for those reagents with short expiration dates.

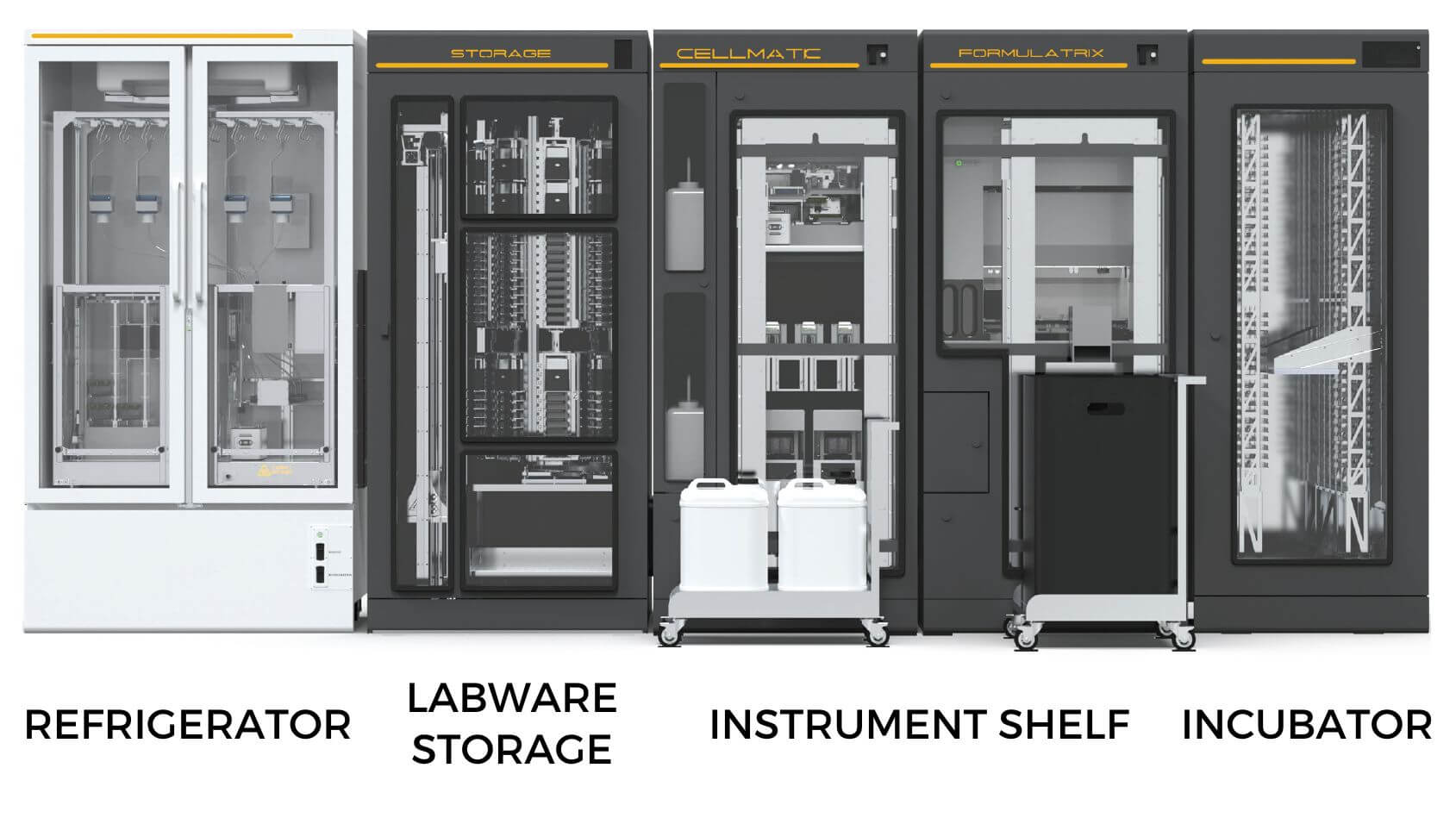

Gentle Plate Handling with ROVER® Autonomous Plate Handlers

The ROVER Autonomous Plate Handlers are wireless, independently driven plate-handling vehicles that move labware throughout the Cellmatic system. The system’s scheduler and ROVER Fleet Manager automatically task individual ROVER to execute transfers. The fleet of ~6 ROVERs in the Cellmatic system drive in and out of the incubator, refrigerator, and processing areas delivering tips, reagents, and cell plates to liquid handlers and imagers. The unique motion profile of the ROVERs allows large volume troughs of liquid and precious cell plates to be transferred with no spilling or disturbance to the cells.

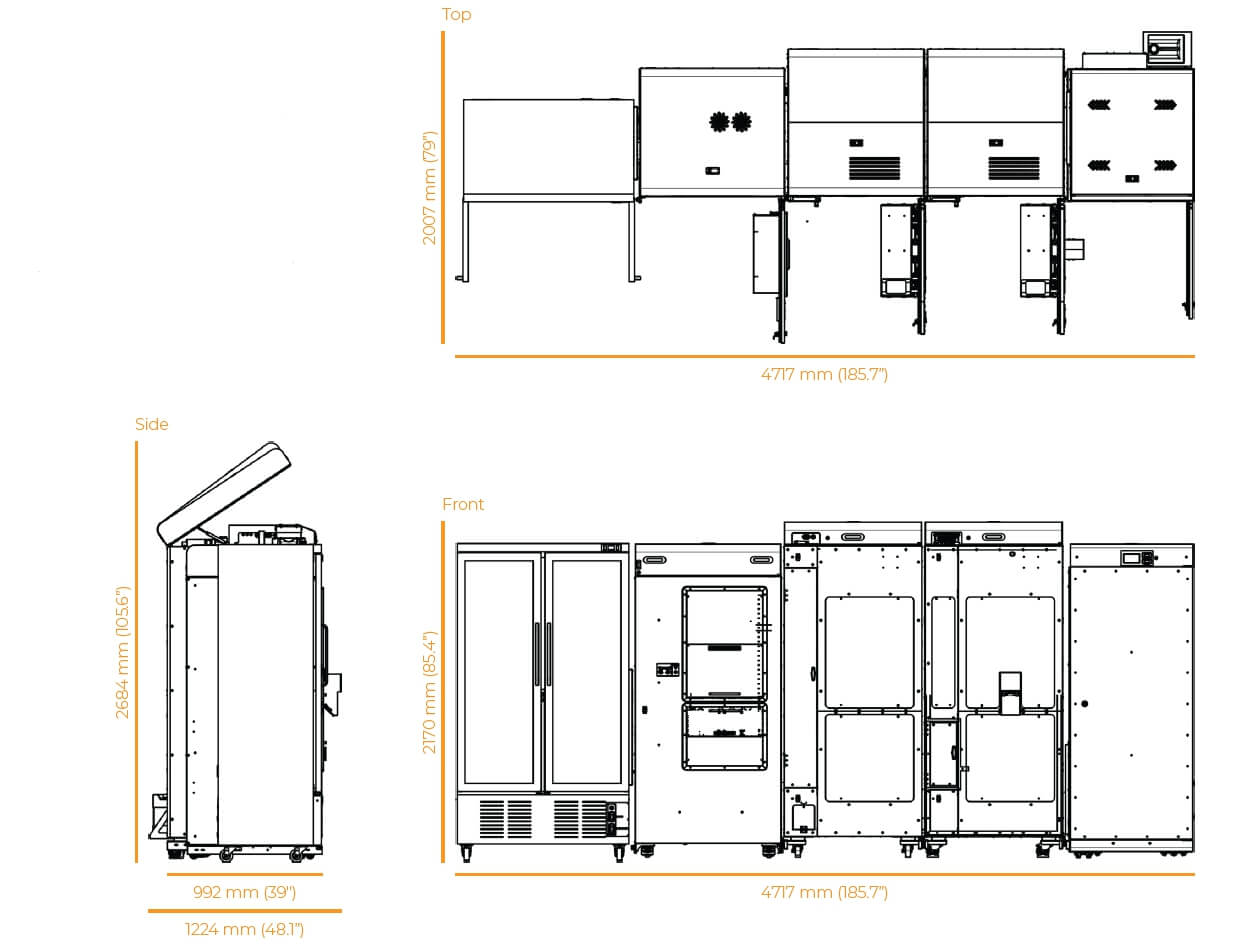

Advanced Technology Integrated into Every Subsystem

- 400 plate capacity incubator with CO2, temperature, and humidity controls

- 4°C refrigerator stores up to 12 base media and 50 specialized reagents for up to 2-3 weeks of run time

- 8 channel, independent z-axis liquid handler (FLO i8) with liquid level detection and choice to reuse or dispose of tips; includes tilting deck

- Ultra-fast reagent exchanger for feeding plates and plating cells into high-throughput multi-well plates

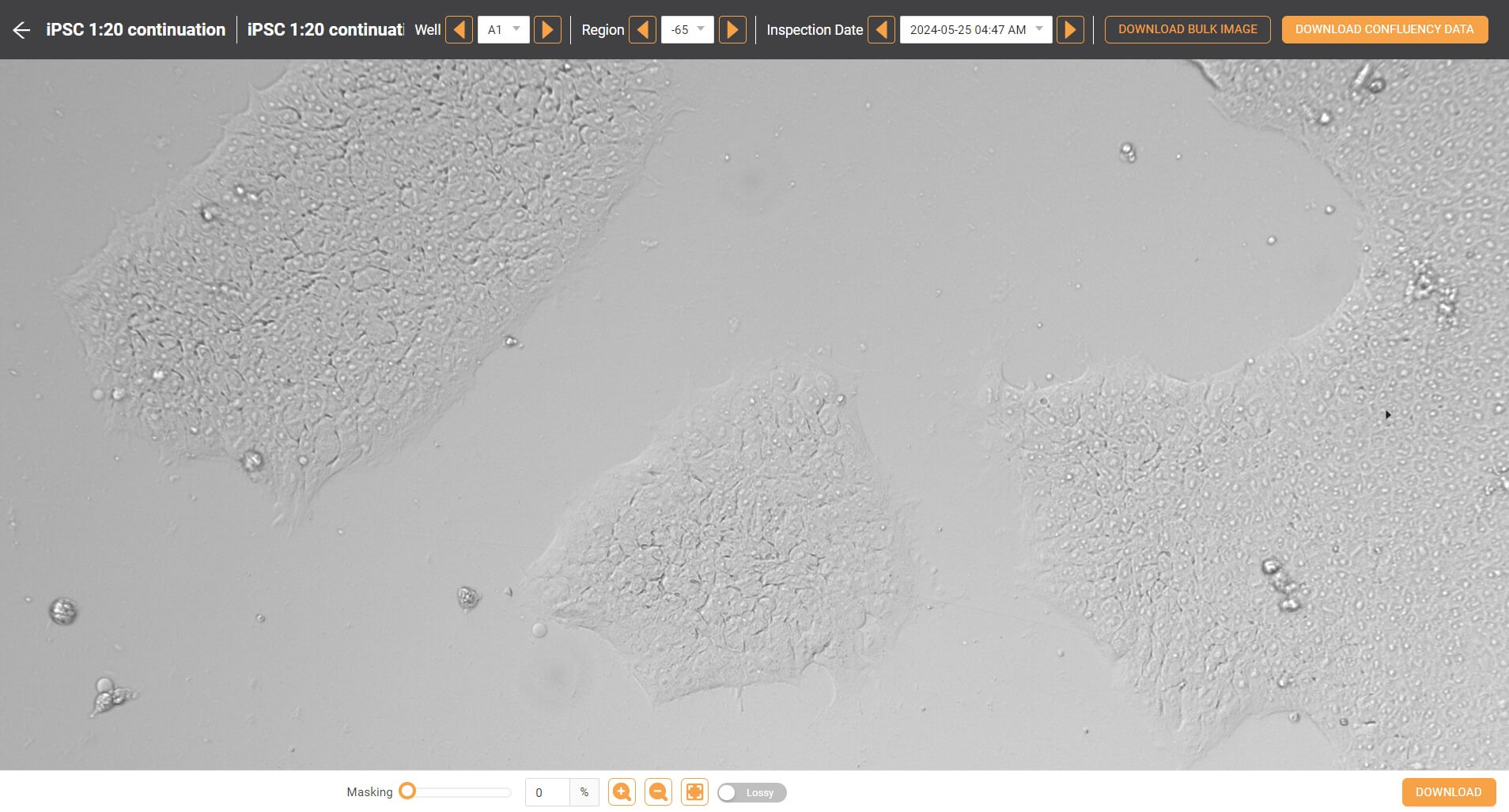

- The confluency reader captures images of the entire 96-well plate in <3 mins

- ROVER Autonomous Plate Handlers carry plates to and from subsystems

- Tightly controlled environment to reduce contamination. HEPA filters throughout with access points under positive air pressure

- The entire system can be sterilized with Vaporized Hydrogen Peroxide (VHP)

Efficient Cell Plating and Feeding - Reduce Cost, Waste and Time

The Reagent Exchanger is a cell plating and feeding liquid handler built into the Cellmatic system. Its reusable tips quickly aspirate spent media and gently dispense new media. Optimized for delicate cells, it also plates cells into 96- and 384-well plates for assay generation.

The system offers various benefits, including:

- Excellent cell plating CVs by continually stirring the cell suspension during dispensing

- Increased cell viability with gentle handling of your cells via non-contact, sidewall dispensing

- Quickly feed your plates - aspirate and dispense a 96-well plate within one minute

- Compatible with 384-, 96-, 8-, 4-, and 1-well plates

- Save on reagents as the system boasts a low dead volume of 500 µL

- Reduce the risk of contamination with automated lidding and delidding

Media Exchange in a 1-well Plate with Nozzle Cleaning

Media Exchange in a 96-well Plate

Need to Expand Cell Lines?

Then let the automation suite handle it for you.

Load the system with a plate of your starting cells, tell it the desired cell number you want, and a few days or weeks later your cells are ready to go. In order to be automation-friendly, the system utilizes one-well, SBS format plates for cell expansion work instead of flasks. The system can output the one-well plates of cells, pool multiple plates into a trough, or plate them into high-density plates depending on your needs. Expand multiple different cell lines in parallel, all while focusing on your research and allowing the system to do the cell expansion work for you.

Intuitive, Web-based Software Designed Specifically for Cell Culture

Users do not script or create protocols as is traditionally done with automation robotics. Instead, users tell the system what end result they are looking for. Culture methods are defined in terms of the trigger for splitting, imaging interval, and passage ratio. There is no need for a step-wise definition of aspirate and dispense sequences. The intuitive scheduler will then interweave all user requests automatically. Results and analysis tools are displayed in an easy-to-follow layout with export tools that link with your own lab notebook systems. Diagnostic routines are performed daily to ensure proper system operation.

Stem Cell Differentiation

Have a 30 to 60-day stem cell differentiation protocol to run?

Trying to design the best protocol to differentiate your stem cells?

Utilize the automated cell culture system to handle your stem cells with the utmost care. The precise 8-channel liquid handler can be used for growth factor additions at user-specified schedules. Phenotypic feedback, such as dendrite length, from the high-resolution imager, can be used to direct protocols automatically. Cells are gently handled with minimal vibrations throughout the entire system and side wall dispensing is utilized for any reagent addition. Protocols can be modified at any time giving you full control of how your stems cells are handled. Protocol progress and results are viewed via the web-based software from anywhere. Increase throughput and reduce variability by having the cell automation suite run your protocols.

iPSCs grown in culture utilizing StemFlex medium and clump passaging with ReLeSR for dissociation