Save Money + Reduce Waste

No additional consumables

are required to run or maintain

the system.

Maintain Ingredient Integrity

Closed containers prevent contamination, evaporation, and the release of fumes.

Build Complex Screens

Use up to 34 ingredients to create custom screens to fit your experiment needs.

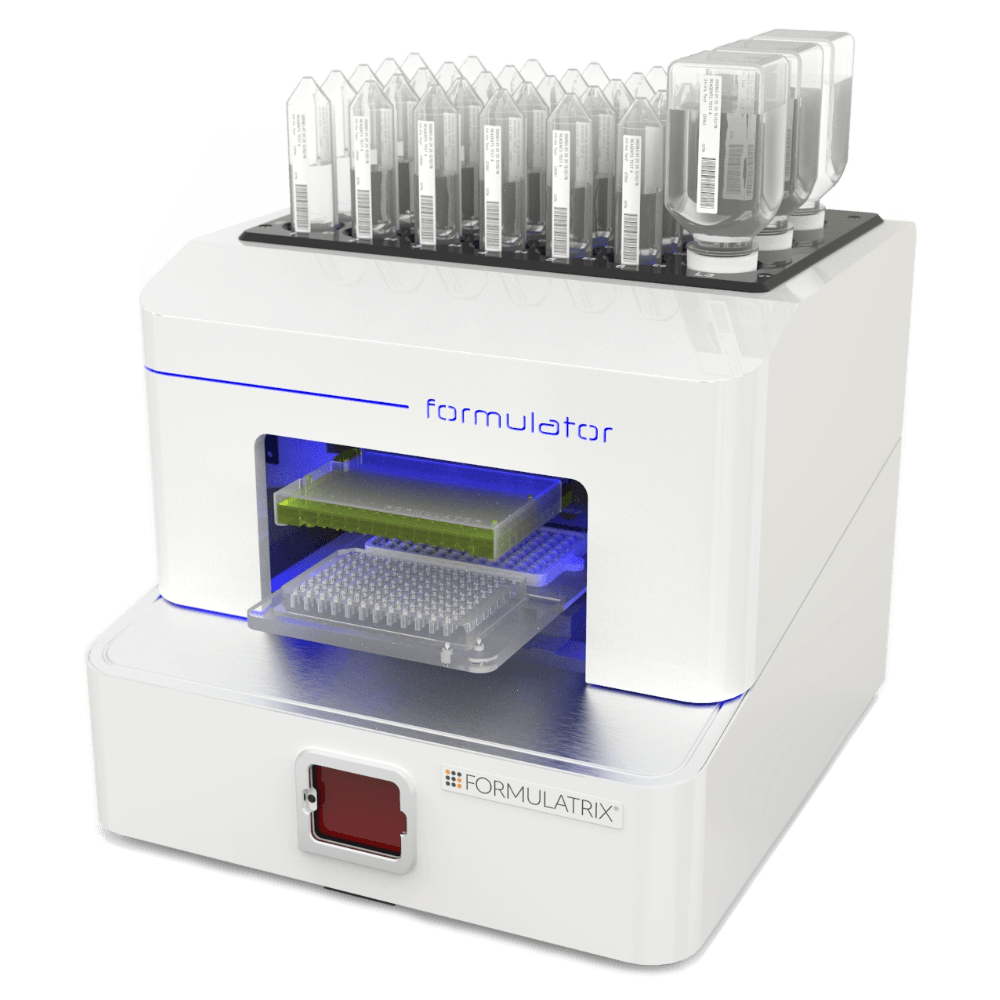

Build Crystallization Screens with Ease

Crystallization hit optimization and custom screen creation are integral parts of crystallographic workflows. The Formulator® is a specialized microfluidic liquid dispenser to create macromolecular crystallization screens. It can dispense up to 34 different ingredients. A 96-nozzle dispensing chip can dispense any volume of any ingredient of any viscosity into any well. It has broad viscosity compatibility necessary to handle various ingredients found in commercial screens.

Flexible Liquid Dispensing

- Low volumes, down to 200 nL with no upper limit

- Dispense a 100 μL, 3-ingredient, 96-well crystallization grid in 2.7 mins

- Supports all SBS-sized plates, VDX/Linbro plates and deep well blocks

Easy Operation

- Integrated barcode scanner automatically loads experiment and ingredient data

- Bottle sensors know where ingredients are located

- Design, Barcode, Scan, and Run

- The only screen builder integrated with Rock Maker® - Crystallization Software

Dispense Viscous and Non-Viscous Ingredients

At the core of the Formulator is a patented microfluidic chip that measures and dispenses discrete volumes of liquid. The chip has 96 outputs, each with its own microfluidic valve cluster. Each valve cluster has two micro-diaphragms (200 nL and 2.5 µL) that fill and dispense up to three times per second. By combining multiple dispenses of each micro-diaphragm, the Formulator can dispense any volume down to 200 nL.

Easily Create Screens with Up to 34 Ingredients

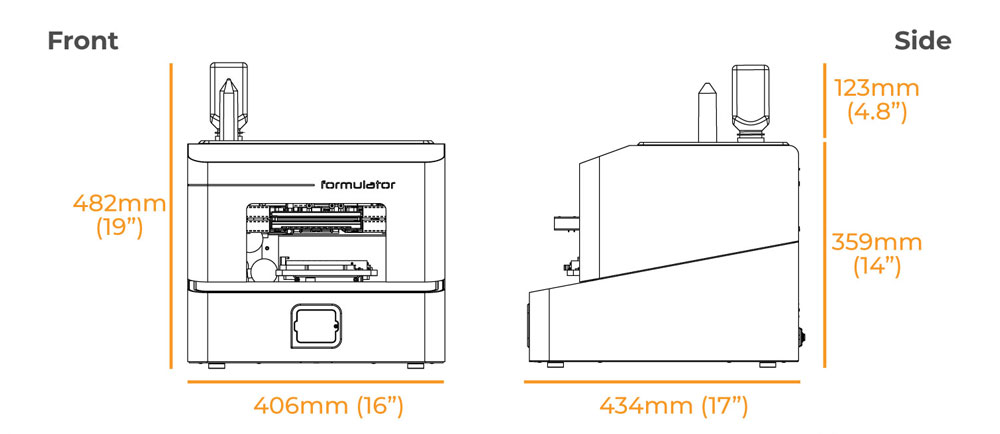

Models to Fit Your Budget and Workflow

The Formulator comes in 3 different models based on the number of ingredients you need to create your crystallization screens. The systems support both 125 mL and 250 mL Nalgene bottles, as well as, 50 mL conical tubes. All of the models have the same physical size and offer an optional secondary wash input for other wash solutions.

Easy Ingredient Switching

Adding ingredients is as easy as scanning the reagent barcode and inserting the bottle (with a specialized check-valve cap) into any open input on the top of the Formulator. Bottle sensors tell the system where you positioned each reagent automatically, eliminating user error.

Formulator 34 Shown

User-Friendly Software

The Formulator software provides a straightforward, user-friendly way to run even the most complicated dispensing protocols through a visual representation of your plate that displays each ingredient’s dispense volume and well location.

Design dispenses that vary the volume of each reagent to every well on the plate, dispense the same volume to every well, and add a backfill if necessary.

Rock Maker Integration

Quickly design experiments using the Rock Maker Crystallization Software. Rock Maker can provide a barcode to print and label your plate with. To run the dispense list, simply scan the plate label using the integrated barcode scanner before placing the plate on the Formulator's plate holder. The dispense design will automatically load and you're ready to run the dispense.

Simply Design, Barcode, Scan, and Run

Gradient Layer Optimization Screen

Random Layer Dispensing