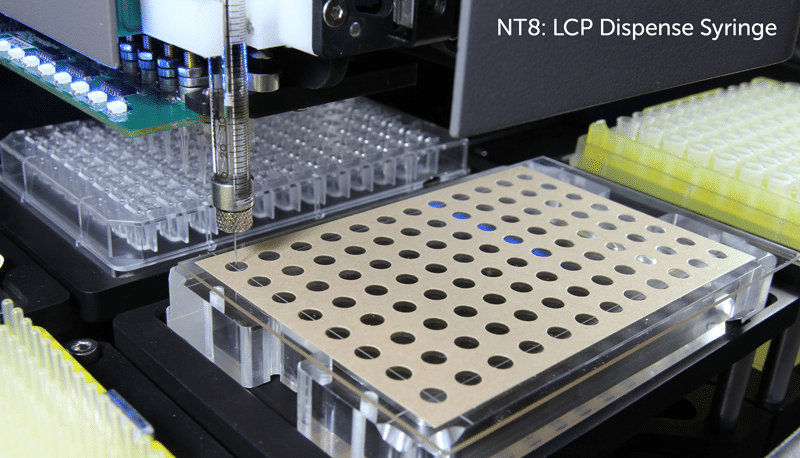

Automated drop setters are common in most laboratories and provide the automation necessary for routinely setting up crystallization plates containing soluble proteins. Unfortunately, extending their use to encompass Lipidic Cubic Phase (LCP) drop setting is not trivial. The LCP medium is highly viscous, making it difficult to dispense reproducible drops in a timely manner. Conditions including syringe pressure, tip displacement, drop volume, dispensing speed, and evaporation rate all impact the reproducibility of LCP drop setting. The recent introduction of LCP-specific drop setters, including the NT8® by FORMULATRIX® , has finally enabled reliable, automated LCP drop setting.

In the case of the NT8, the velocity of the syringe plunger, and the delay before moving the stage are carefully optimized in order to set uniform drops. The compression forces experienced by the LCP medium vary with the speed at which the plunger is actuated, resulting in medium dispensing after the plunger has stopped moving. In the NT8, the delay before moving the tip away from the plate after the plunger has been actuated is carefully calibrated, resulting in uniform and reproducible drops.

Due to the high viscosity of the medium, LCP dispensing is more time-consuming than soluble-protein drop setting. In general, dispensing of soluble proteins in a 96 well plate takes about 2 minutes, whereas the same operation utilizing LCP requires about 7 minutes. The longer times required cause evaporation to become a greater issue than during conventional drop setting. In order to combat evaporation during dispensing, the NT8 employs three individual ultrasonic humidifiers that control the relative humidity of the environment up to 95%.