Automated TFF Built for High-Throughput Processing

The aµtoPulse is a fully automated, walk-away system that uses tangential flow filtration for high-throughput sample concentration and diafiltration (buffer exchange, desalting).

High-Throughput

Process up to 54 samples per run, with up to four samples operating in parallel under independent pressure control. The system can be configured to match specific applications and throughput requirements.

Lowest Hold-Up Volume, Industry-wide

Achieve maximum yield and minimal waste, run after run. The aµtoPulse features the lowest hold-up volume in the industry, enabling recovery to just 250 µL final volume - ensuring more of your sample proceeds to analysis and less is wasted in the system.

Flexible Operating Volume

Process volumes from 0.5 to 100 mL, without compromising efficiency.

High Flux Performance

Accelerate your timelines without sacrificing the integrity of your samples. Engineered with high-performance dual diaphragm pumps, the autoPulse delivers permeate flow rates up to 4x faster than traditional centrifugal dead-end filters.

Flexible Buffer Management

Support a vast range of applications by utilizing four external buffer reservoirs for large volumes, or leverage on-deck conical tubes for streamlined, smaller workflows.

Automated Cleaning-in-Place

Eliminate the risk of carryover with automated Cleaning-in-Place (CIP). The aµtoPulse automatically flushes and rinses the entire liquid path between every run, ensuring optimal conditions for every sample. The fully consumable sample fluid path minimizes cross-contamination and simplifies maintenance.

Fast

The innovative chip design allows 4x faster processing compared to traditional dead-end filtration

High-Throughput

Process up to 54 samples per run, with up to four samples operating in parallel under independent pressure control

Full Automation

Automate the entire workflow from cleaning to sample recovery with remote monitoring and no user intervention

Run More Samples with Less Effort

Efficiency is about more than just raw throughput—it’s about simplifying your daily operations. With the aµtoPulse, you can load up to 54 samples, define your parameters, and walk away. Import labware definitions directly via upstream dispense lists and re-run saved protocols to guarantee consistent, reproducible results every time.

From automated cleaning to final sample recovery, the aµtoPulse manages the entire cycle. It automatically advances through your queue without intervention, while the intuitive software allows for remote monitoring, allowing researchers to focus on higher-value scientific work.

Run Versatile Samples

Efficiently process lipid nanoparticles, liposomes, and polymeric nanoparticles for drug delivery and therapeutic efficacy

Optimize the protein preparative workflow, enabling fast and gentle processes, including concentration, formulation, desalting, and refolding

Ensure gentle and efficient removal of small unconjugated molecules from a variety of crude biomolecular labeling reactions

Simplify in vitro synthesis of RNA, and linear or plasmid DNA, by efficient concentration and buffer exchange using our user-friendly system

Streamline the fast harvesting of cells, extracellular vesicles, enzymes, and Virus-Like Particles (VLPs) while ensuring high product yields and quality

Gently concentrate and exchange buffers for Adeno-associated Virus Vectors (AAVs), bacteriophages, and lentiviruses, preserving their structure for effective applications

Optimize the formulation of DNA, RNA, and polysaccharide vaccines for optimal, stable, and cost-efficient results

Concentrate Samples Faster with Greater Control

Unlike dead-end filtration units, the aµtoPulse prevents high concentration gradients from forming at the filter surface, helping maintain permeate flow and improve sample recovery.

Dual diaphragm TFF provides a continuous concentration process and controllable pressure gradient, reducing sample stress and enabling up to 4 times faster concentration than dead-end filtration. Improved back pressure regulation allows transmembrane pressure ranges from 0-37 psi, with independent control and monitoring at each concentration station.

The aµtoPulse supports reliable concentration across both low- and high-volume workflows within a single integrated system. Consistent performance is maintained as sample volumes vary, helping preserve sample integrity and recovery. This flexibility reduces the need for multiple setups and enables experiments to run with minimal hands-on time.

Low Volume Sample Concentration

Concentration of 100 mL Sample

Optimize Your Diafiltration Protocol

The aµtoPulse provides automated diafiltration to support desalting and buffer replacement workflows with minimal user intervention. Buffer exchange can be performed using on-deck tubes or external reservoirs, allowing workflows to be adapted to different sample volumes and throughput needs.

Intelligent volume monitoring enables samples to be concentrated to defined setpoints before each exchange cycle, helping maintain consistent conditions throughout the process. Programmable exchange steps, real-time monitoring, and automated final concentration deliver highly reproducible results while significantly reducing hands-on time.

Buffer Exchange Using On-Deck tubes

Buffer Exchange Using External Reservoir

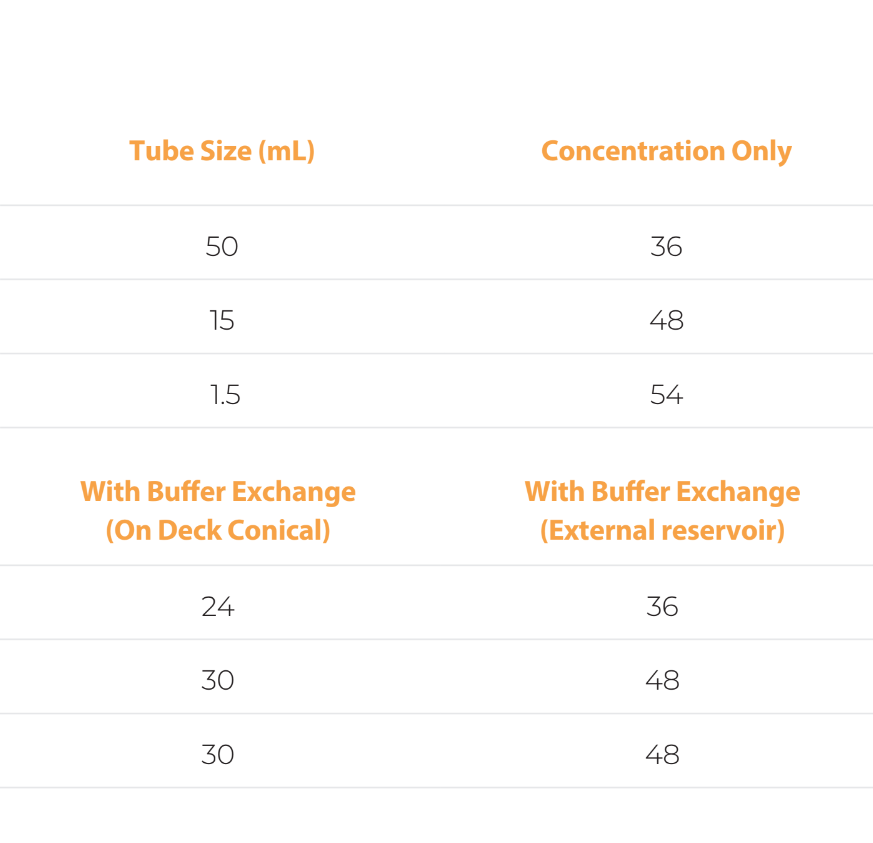

Setup to Match Your Throughput

Max Sample Count per Run

| Tube Size (mL) | Concentration Only |

With Buffer Exchange (On Deck Conical) |

With Buffer Exchange (External Reservoir) |

|---|---|---|---|

| 50 | 36 | 24 | 36 |

| 15 | 48 | 30 | 48 |

| 1.5 | 54 | 30 | 48 |

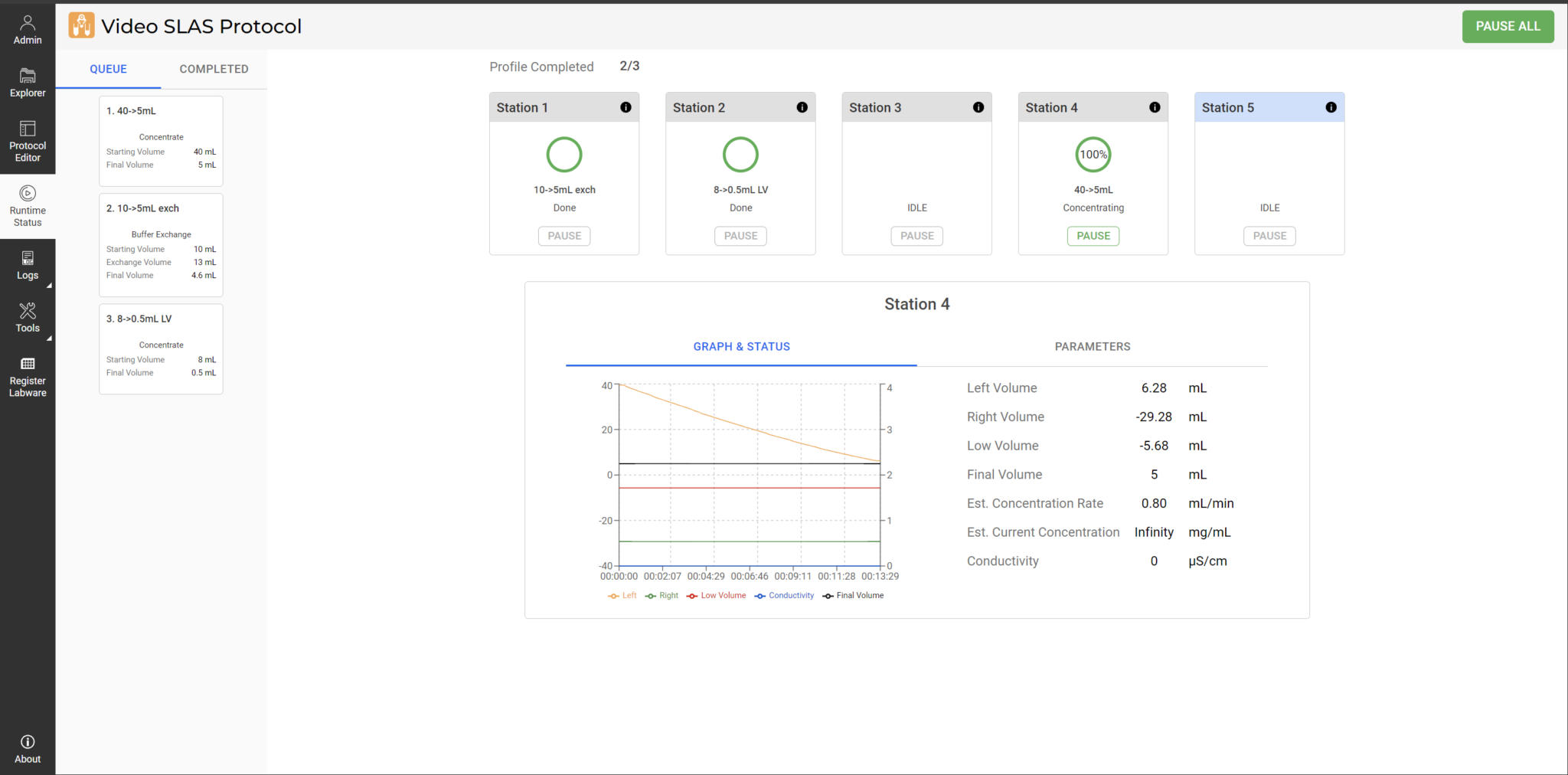

Simplify Setup and Monitor Remotely

Complexity shouldn't mean a steep learning curve. The aµtoPulse features an intuitive, web-based interface that puts total process control at your fingertips—whether you’re standing at the bench or working from your desk. Easily set up sophisticated, multi-step protocols—including sequential concentration and buffer exchange—with a simple, intuitive interface. Track your run’s progress, pressure readings, and volume setpoints in real-time from any device on your network. Fine-tune advanced settings for your samples and save the protocols to ensure identical, optimal execution across every run.

Eliminate Cleaning and Cross Contamination

Maintaining performance also depends on keeping the fluid path clean and free of contamination. The re-invented disposable filter chips integrate transfer tubing to create an entirely consumable sample path. Dedicated cleaning stations link directly to external reservoirs, allowing the system to wash and rinse the entire path automatically between runs.

User-defined cleaning protocols allow you to automate buffer rinsing, ensuring the flow path is equilibrated to optimal conditions before the next sample is processed.

FAQs

What makes the aµtoPulse - TFF system different from the µPulse system?

The µPulse processes a single sample per run, while the aµtoPulse - TFF system can process up to 54 samples, making it ideal for high-throughput workflows. It also features a lower hold-up volume (250 µL) compared to 650 µL in the µPulse, ensuring higher recovery from small or precious samples. While both systems use the same gentle microdiaphragm pumping technology, the aµtoPulse - TFF system introduces full automation and parallel processing capabilities that significantly increase efficiency.

How does the aµtoPulse - TFF system achieve the industry's lowest hold-up volume in tangential flow filtration?

The aµtoPulse - TFF system achieves the industry’s lowest hold-up volume—as low as 250 µL—through its miniaturized flow path design and integrated microdiaphragm pumping technology. This design minimizes dead volume by shortening the fluid path and optimizing internal geometry for efficient fluid displacement.

How does the dual-diaphragm pumping technology in the aµtoPulse - TFF system improve permeate flow rates and processing speed?

The aµtoPulse - TFF system uses dual-diaphragm pumping technology to maintain a continuous and stable flow across the TFF membrane. While one diaphragm pushes fluid through the membrane, the other refills simultaneously, eliminating the stop-and-start motion seen in single-pump systems. This synchronized operation ensures uninterrupted flow, which leads to higher permeate flux and faster processing speeds.

What transmembrane pressure range does the aµtoPulse - TFF system support for optimized sample control?

The aµtoPulse - TFF system supports a customizable transmembrane pressure (TMP) range, typically up to 32 psi. This range ensures gentle, efficient handling of diverse samples by allowing precise control over filtration dynamics. Consistent TMP regulation minimizes membrane fouling and maximizes product recovery.