Volume Range

Min: 0.2 µL

Max: 1000 µL

Technology

Positive

Displacement

Precision

CV <5%

@ 0.5 µL

The Re-Engineered FLO i8®, Now with Positive Displacement

and Non-Contact Dispensing

Liquid Class Agnostic Pipetting – Handle a wide range of liquid viscosities with positive displacement tips without programming liquid classes

Save Time and Cost - The FLO i8 PD offers non-contact dispensing for rapid aliquoting with minimal tip usage, saving you time and money

Incredibly Easy Software – Design your protocol with ease using our intuitive, drag-and-drop interface

Flexible – Simplify all of your tube and plate-based labwork using the independent spanning channels with a pipetting range of 0.2 μL to 1000 μL

Intelligent – Automatically locate labware and detect and track liquid levels with sensing technology built into each pipetting channel

Precise – Reduce variability in your workflows while increasing your traceability and confidence in your experiments (CV <5% at 0.5 µL)

Automation-Friendly – The FLO i8 PD’s software offers an open API for seamless integration

FLO i8 PD Liquid Handler - Positive Displacement Pipette Tips

Save Time and Money on

Low Volume Transfers

Reduce reagent consumption and cut costs with non-contact droplet dispensing, enabling precise aliquoting down to 200 nL

Flexibility with Best-in-Class

Precision

Pipette any sample from any labware with unmatched precision using positive displacement, fully independent channels

Go from Zero to Running

Experiments in Minutes

Launch experiments in minutes with a simple, intuitive interface—no complex programming or coding expertise required

Automate Your Benchwork with Ease

Broad Range of Applications

- Assay Development and Design of Experiment (DoE)

- Enzyme-Linked Immunosorbent Assays (ELISA)

- PCR Workflows

- Cell Culture and Bead-Based Assays

- NGS Library Preparation

- Nucleic Acid and Protein Extraction

- Screening Assays (e.g., COVID)

- Lipid Nanoparticle (LNP) Formulation Screening

The FLO i8 PD liquid handler is ideal for optimizing your protocols and bench work, allowing you to focus on the research. Featuring intuitive software, flexible hardware, and positive displacement technology, the FLO i8 PD takes the guesswork out of liquid handling automation by ensuring precise liquid transfers without the need to specify:

- Source volumes

- Well geometries

- Liquid properties

Save Time and Costs with Non-Contact Droplet Control

The FLO i8 PD features non-contact droplet dispensing, enabling precise aliquoting down to 200 nL. This innovative system enables miniaturization, cuts tip costs, and streamlines workflows. Combined with its liquid class-agnostic positive displacement pipetting, the system effortlessly handles a wide range of liquids, including viscous and volatile types, delivering rapid and reliable results with minimal consumable use.

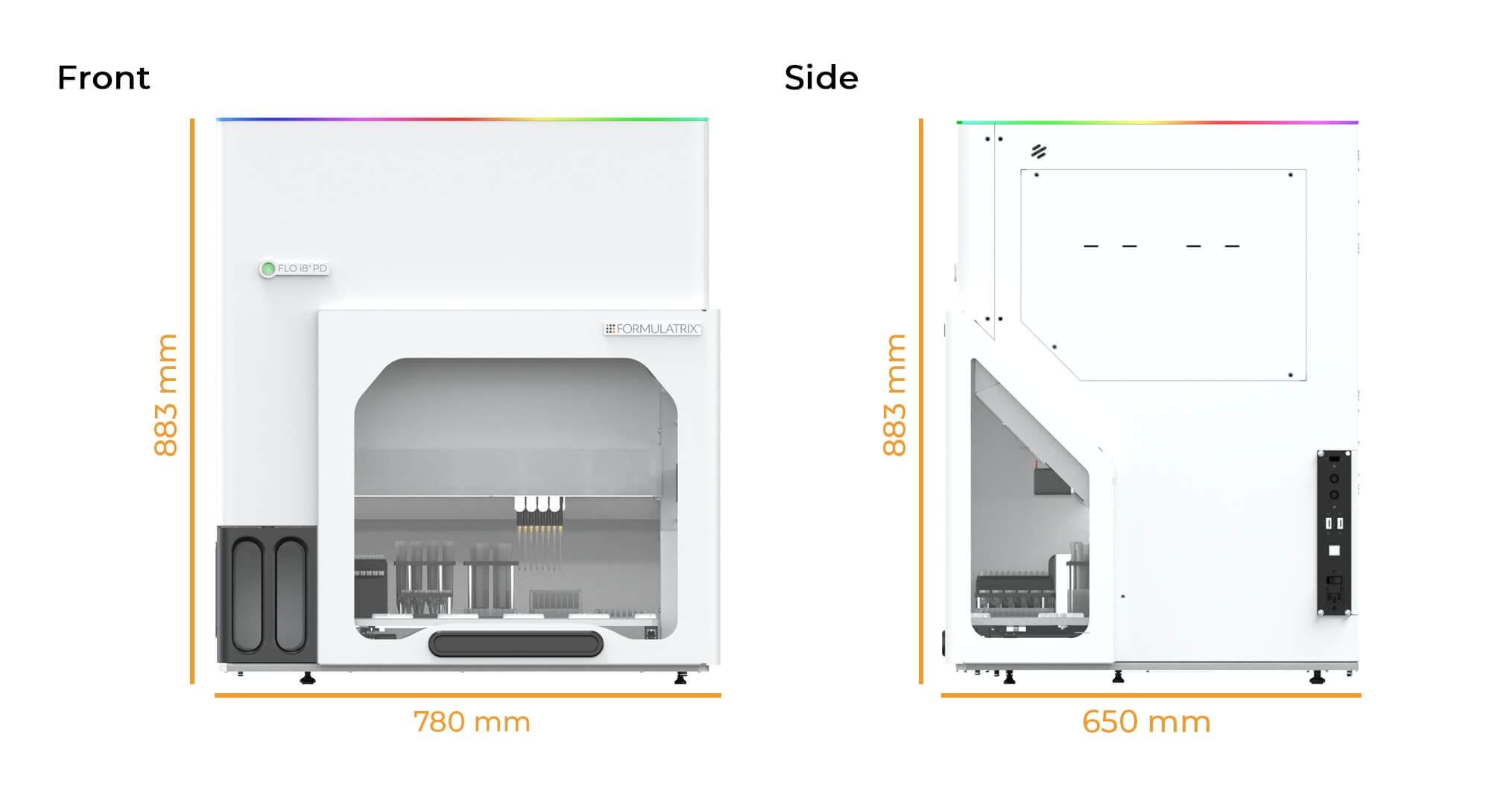

FLO i8 PD Liquid Handler - Hardware Overview

Overview of the FLO i8 PD

Key Features

- 8 fully independent positive displacement channels

- Non-contact droplet dispensing

- Wide volume range (200 nL - 1000 µL)

- Intuitive software

- Liquid Class Agnostic

- Intelligent liquid-level detection and tracking

- Precise and accurate transfers

- Smooth deck motion

- Vision-based scanning to locate tips and labware

- Sense of touch embedded into each channel

Agnostic Pipetting: Any Liquid, Any Volume

For years, liquid handlers have struggled with transferring liquids of varying viscosities and surface tensions due to time-consuming liquid class optimization. Finally, Formulatrix has developed a liquid handler that automates this process.

The FLO i8 PD effortlessly handles a wide range of liquids, from aqueous solutions to highly viscous fluids up to 100 cP, as well as volatile liquids, minimizing sample loss and contamination. The positive displacement tips allow users to pipette virtually any liquid in any volume without needing to program liquid classes.

A Liquid Handler That Optimizes Pipetting So You Don't Have To

Our liquid handler with 8 independently spanning channels simplifies experimental design, setup, and execution. The hardware offers the flexibility to handle any labware or liquid you throw at it, and the intuitive software makes it easy to define your workflow. With real-time progress monitoring, intelligent channels and tips, and positive displacement precision, the FLO i8 PD will be the lab partner you can't live without.

Design Your Experiment in Minutes

The FLO i8 PD liquid handler breaks the mold of traditional systems with its intuitive, user-friendly interface and intelligent design. The UI makes even complex workflows straightforward, offering both drag-and-drop transfer mapping and the option to import a .csv worklist.

By designing a system that combines gold-standard pipetting hardware with intelligent sensing, we’ve reduced protocol creation to just one step: design your protocol. FLO i8 PD handles everything from simple liquid transfers to complex tasks you still perform manually, increasing experimental fidelity while reducing bench time.

With the FLO i8 PD, Formulatrix empowers efficient, reproducible research to drive scientific discovery. The system is designed to be so user-friendly that anyone in your lab can quickly become a power user.

Dynamic Liquid Level Detection and Tracking

The FLO i8 PD takes liquid level detection and tracking to the next level with sensors that enable dynamic liquid level tracking without prior definition of labware well profiles. Scientists can focus on their experiments instead of programming surface positions and complex labware parameters.

"Software was surprisingly intuitive and quickly adopted in my group."

Huy Nguyen

Scientist at Genentech

Don’t Stress Over Well Geometry

Tip touch sensors can find the bottom and sides of each well, so you don’t need to program the specific geometry of your labware.

The pipette touch sensors also facilitate best-in-class error management and safety by detecting collisions with obstructions and halting motion. Researchers can simply remove the obstruction, and the FLO i8 PD will continue from where it left off.

Simplify Setup with Vision-Based Deck Scanning

The FLO i8 PD liquid handler features a vision system with automatic tip and labware detection. Before each run, the camera scans the deck to confirm labware placement and verify that there are sufficient tips for the protocol. It identifies the size, number, and location of tips so users never have to rearrange tip caddies.

This functionality simplifies setup and reduces the risk of user error, allowing researchers to focus on more critical tasks.