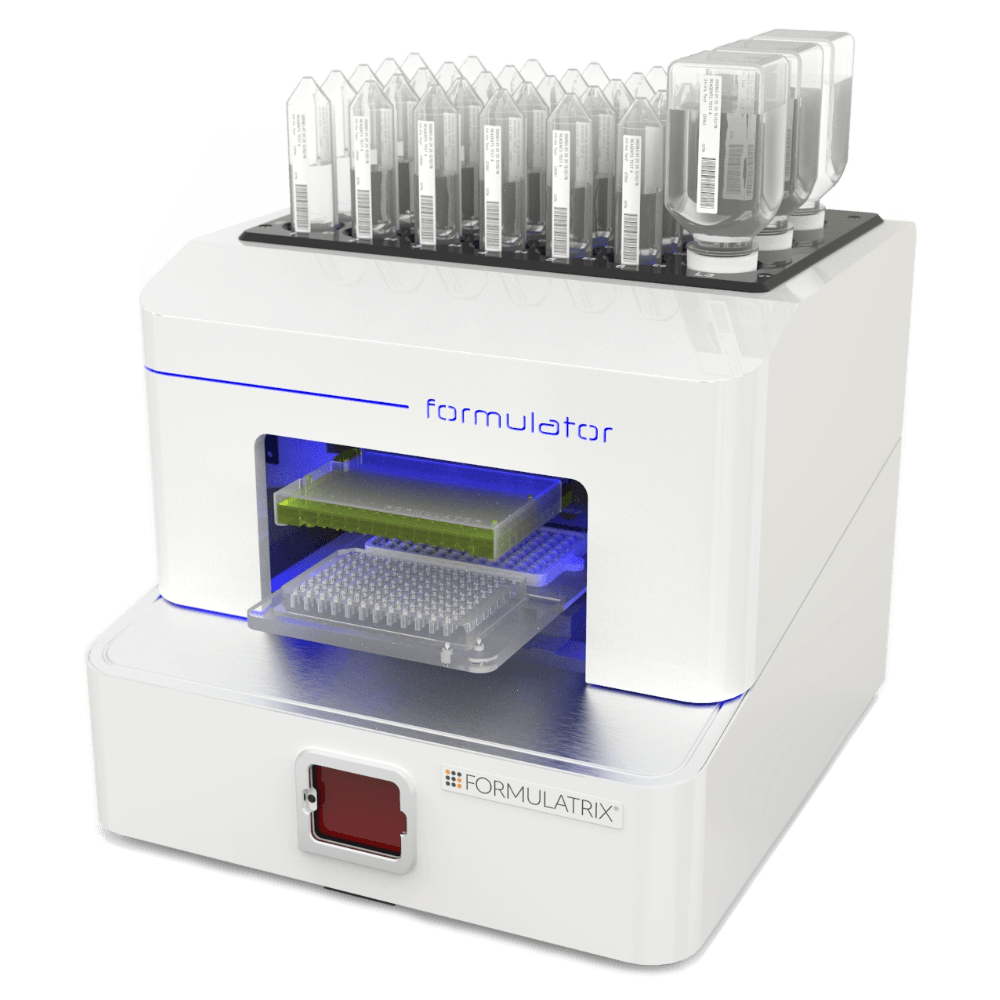

General Overview & Capabilities

How does the Formulator Screen Builder improve protein crystallography screen preparation compared to manual methods?

Manual screen preparation for protein crystallography is a complex, time-consuming, and error-prone process, as it requires precise dispensing of multiple ingredients in varying volumes into each well. The Formulator Screen Builder simplifies and accelerates this process using advanced microfluidic liquid dispensing technology. Its 96-nozzle dispensing chip can accurately dispense any volume of any reagent, regardless of viscosity, into any well, enabling rapid, precise, and reproducible screen preparation.

Does the Formulator produce consistent and reproducible crystallization screens across multiple batches?

Yes. The Formulator ensures consistent and reproducible crystallization screens by allowing users to save and reuse dispense protocols or dispense lists. This capability is particularly valuable for preparing standard screens or frequently used formulations, ensuring accuracy and repeatability across multiple batches.

Can the Formulator create both standard crystallization screens and fully customized crystallization conditions?

Yes. The Formulator can prepare both standard commercial crystallization screens and fully customized formulations, allowing complete flexibility to design and optimize conditions tailored to specific experimental needs.

How effectively does the Formulator handle viscous, volatile, or sticky reagents like PEGs, salts, and organics?

The Formulator efficiently handles a wide range of reagent viscosities, from low-viscosity solvents to highly viscous PEGs and sticky organics. Users can define liquid classes—from normal to very high viscosity—to ensure accurate dispensing. By organizing viscous reagents earlier and low-viscosity ones later in the dispense list, the Formulator builds the optimal pressure profile to dispense all reagents precisely and consistently.

Can the Formulator generate gradients or fine-tuned reagent concentrations for crystallization optimization?

Yes. The Formulator can easily generate precise reagent concentrations and a variety of gradient types, including horizontal, vertical, forward diagonal, and backward diagonal gradients, for crystallization optimization experiments. This enables fine-tuned control over experimental conditions to identify optimal crystallization parameters efficiently.

How much time can labs save by using the Formulator compared to preparing screens manually?

The Formulator can save several hours of manual work by automating the preparation of crystallization screens, allowing researchers to focus on data analysis and experiment optimization instead of repetitive pipetting tasks.

Is the Formulator suitable for both small academic labs and high-throughput crystallography facilities?

The Formulator comes in three different models (Formulator 10, 16, and 34), depending on the number of ingredients needed to prepare crystallization screens. All models share the same compact footprint, support 50 mL conical tubes as well as 125 mL and 250 mL Nalgene bottles, and offer an optional secondary wash input for alternative wash solutions. This flexibility makes the Formulator ideal for both small academic labs and high-throughput crystallography facilities.

How does the Formulator enable flexibility and customization in designing protein crystallography screens?

The Formulator offers full flexibility in screen design by allowing users to precisely control the composition and volume of each well. With 96 independently controlled nozzles, it can dispense different reagents with varying viscosities and volumes into every position, supporting commercial screens, custom gradients, and nonstandard screen formats. Its software enables easy recipe creation and modification, making it ideal for designing unique crystallization conditions tailored to specific protein requirements. Rock Maker integration further streamlines the process of screen design and dispensing.

Software, Operation & Integration

Does the Formulator software include recipe libraries, automated calculations, and repeat-run capabilities?

The Formulator software itself does not include built-in screen recipe libraries; however, this feature is available through integration with Rock Maker. The software can automatically calculate reagent volumes and estimate dispense times for each protocol. Additionally, dispense protocols can be saved and re-run at any time, ensuring consistency and efficiency in repeated screen preparations.

Is the Formulator software intuitive for new users, and how quickly can lab staff become proficient?

Yes. The Formulator software features a simple and intuitive interface, making it easy for new users to learn. Most lab staff become proficient after just a demonstration or a single training session.

How does integration with Rock Maker Crystallization Software enhance the Formulator’s usability?

Integration with Rock Maker greatly enhances the Formulator’s usability by streamlining screen design and dispensing. Rock Maker provides an extensive library of commercial screens from multiple vendors, allowing users to simply drag and drop screens or design fully customized ones using its built-in ingredient database. Screens are visually displayed on a canvas, making it easy to review well compositions and reagent concentrations. Once designed, a barcode can be printed and attached to the plate—scanning it with the Formulator automatically retrieves all screen details from Rock Maker, enabling quick and error-free dispensing setup.

Can I pause a dispense run and resume it later?

Yes. The Formulator supports pausing and resuming a dispense run mid-operation.

Can I recalibrate a single nozzle or ingredient line?

Yes. The Formulator software allows calibration of individual ingredients if you notice dispensing discrepancies. This ensures accuracy without needing to recalibrate the entire system.

Does the Formulator require internet access to operate?

No. Internet access is not required for regular operation. However, network access may be needed for integration with other software (e.g., Rock Maker) or for remote support and updates.

How can I verify that the correct ingredient was dispensed into each well?

The software logs every step of the dispense run. You can cross-reference the dispense report to verify that the correct ingredients and volumes were used.

Will there be an error message if you attempt to dispense a volume below the Formulator’s minimum dispensing limit?

Yes. If you design an experiment in Rock Maker with volumes below the Formulator’s dispensing limit, the software will display an error message. It may suggest using a different variation of the stock solution (e.g., a higher or lower concentration) to stay within the dispensing limits. These prompts are designed to guide you in creating experiments that the Formulator can execute reliably.

Hardware, Dispensing & Performance

Which plate types are compatible with the Formulator?

The Formulator can dispense into 384-well, 96-well, 48-well, and 24-well plates (and other formats) as long as they follow the SBS footprint. Plates that do not fit properly in the Formulator can be used with the help of an adapter.

What is the lower dispensing limit of the Formulator?

The lower liquid dispensing limit for the Formulator is 200 nL.

What is the dead volume of the system?

The total dead volume is 7 mL, which includes 2 mL from the bottle to the ingredient selector and an additional 5 mL from the ingredient selector to the chip.

What is the coefficient of variation (CV) for the Formulator?

The Formulator achieves a CV of 5% or better for volumes of 10 µL and above, and also maintains 5% or better CV for 200 nL dispenses. It has been successfully tested with viscous solutions, including up to 30% PEG 20K.

What are the vacuum and pressure settings?

The vacuum is 22 inHg, and the pressure is 30 psi.

Is there pressure in the ingredient bottles?

No. Liquid is moved into the Formulator by diaphragm pumps within the instrument.

Does it plug or clog easily?

The Formulator is designed with progressively narrowing channels that lead to the dispensing nozzles. During the wash cycle, which runs after dispensing each ingredient, fluid flows in reverse through these channels. This reverse-wash mechanism helps flush out any potential blockages, ensuring consistent performance and minimizing clogging.

Which material is used to make chip valves?

Chip valves are made of silicone.

How quickly can I switch reagent bottles on the Formulator?

It takes about 13 seconds for the Formulator to complete the bottle input wash, which is recommended before changing bottles.

What are the manufacturer’s part numbers for the Falcon tubes and Nalgene bottles that match the septa caps?

The Falcon tubes included in the accessories kit with part number 202300 work only with the septa caps for Falcon #201947. The Nalgene bottles included in the accessories kit, part number 202176, work only with the septa caps for Nalgene #201946.

Does the reagent being dispensed come into contact with the inner workings of the solenoids?

No. The solenoids are located in the main part of the instrument and control air pressure lines that lead to the silicone diaphragm valves in the chip (dispense head). Liquid only contacts the Topas chip and the silicone valves.

What reagents can and cannot be dispensed with the microfluidic chip of the Formulator?

Since we use silicone valves, the Formulator can dispense anything compatible with silicone. The microfluidic chip is made of Topas, which is compatible with most polar liquids but not with non-polar liquids such as oils and xylene. For a list of reagents that should not be used, refer to the chemical compatibility list.

Can I use an older bottle of PEG with material floating inside for dispensing with the Formulator?

The Formulator will operate fine. However, dispensing a solution containing debris may temporarily clog the system or disrupt plate dispensing.

What is the maximum aliquot size per well? I want to dispense into a deep well block (96-well).

There is no maximum well volume. The Formulator can dispense into 2 mL deep well blocks. Simply repeat the dispense cycle to achieve the desired well volume.

Can the software compensate for liquids moving more slowly in a 4 °C room?

It does not automatically compensate for lower temperature operation. You need to set up different liquid classes for 4 °C according to the liquid viscosity.

What are the most viscous solutions that the Formulator can handle in a 4 °C environment?

Anything with a viscosity greater than 5000 cP would be too slow for convenient use.

Cleaning, Maintenance & Cross-Contamination

Do the Formulator tips clean themselves automatically, or do you have to instruct it to clean afterward?

Cleaning is fully automatic. The tips, nozzles, and microfluidic channels are thoroughly cleaned after every ingredient dispense—no manual input is needed for daily use. However, you can adjust the cleaning settings to make the wash cycle more aggressive if desired.

What solutions are used to clean the system?

The system follows a complete cleaning regimen (refer to the chemical compatibility list for details). For routine daily cleaning, water is primarily used.

What’s the best way to remove stubborn residues from the chip or nozzles?

You can use compatible solvents such as 10% ethanol or isopropanol, followed by water rinses. Avoid using aggressive acids or non-polar solvents.

What is the risk of cross-contamination?

With a 10-second wash, cross-contamination is currently less than 1 part per 10,000. Longer washes or secondary washes using cleaning solutions can further reduce cross-contamination.

Setup, Safety & Practical Use

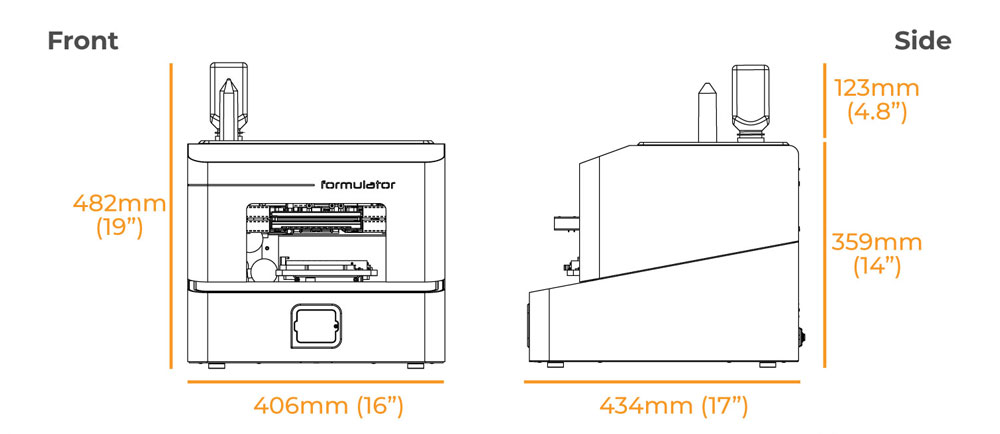

What are the space requirements for installing the Formulator on a lab bench?

The Formulator has a compact footprint and does not require much lab space. With dimensions of approximately 406 mm in width and 482 mm in height (including bottles), it fits comfortably on a standard laboratory bench.

Does the Formulator help reduce long-term laboratory costs compared to buying commercial crystallization screens?

Yes. The Formulator significantly lowers long-term laboratory costs by enabling researchers to prepare custom crystallization screens in-house using different stock solutions, eliminating the need to purchase expensive commercial crystallization screens.

If a drip or spill occurs on the top of the system, can it be cleaned easily?

Yes. The system is designed to handle such situations. It includes a drip tray at the top with a drainage port, allowing any spilled reagent to exit safely and making cleanup straightforward.

Can the Formulator operate without barcodes on ingredient bottles?

Yes. The Formulator can function without barcoded bottles. If barcodes aren’t used, simply place the ingredient bottles on the Formulator. When the ingredients appear as red boxes in the Inputs window, manually drag the correct chemical from the Dispense List to the corresponding position in the Inputs window, and you’re all set.