Less Time at the Centrifuge, More Time for Research

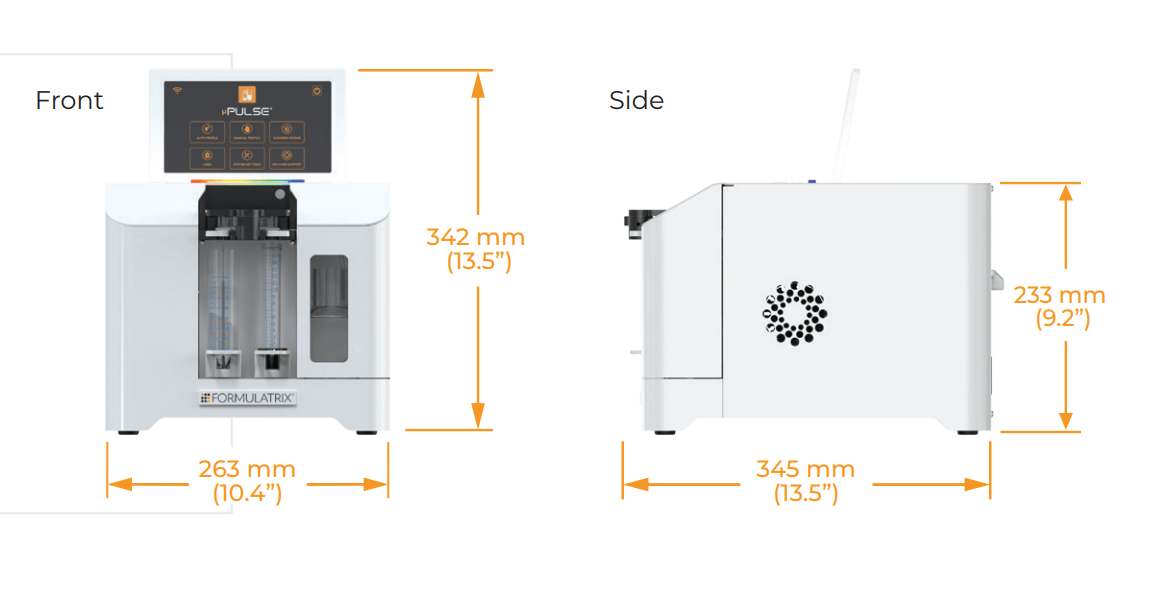

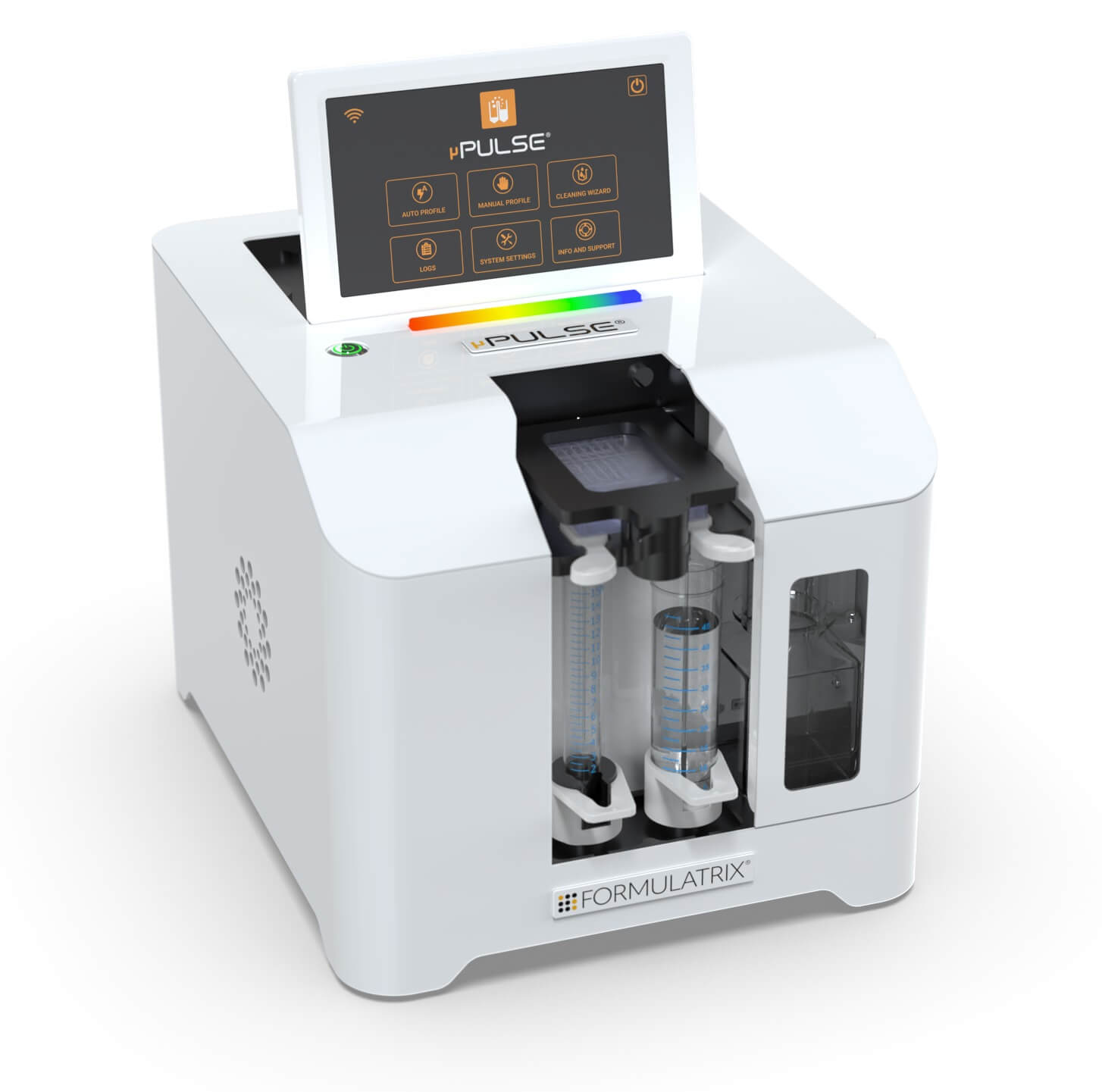

The µPulse® - TFF System is a fully automated, walk away system that uses tangential flow filtration (TFF) for sample concentration and diafiltration (buffer exchange, desalting).

Walk-Away System

Set your desired parameters and let the system do 95% of the process automatically until it is time to collect your sample; Remotely monitor via a web-based application.

Fast

Permeate flow rate up to 4x faster than centrifuges with dead-end filters.

Scalable Process

Whether you are trying to scale up or down, µPulse allows you to control all the parameters of an industrial TFF, at the research scale.

Wide Range of Operating Volumes

Concentrate from 100mL to 1mL with up to 250 mL of buffer exchange.

Lowest Hold-up Volume in the Industry

Our patent-pending pump design offers just 0.65 mL of hold-up volume. Up to 100% hold-up recovery with automated recovery options.

Easy Maintenance

All components in the fluid path are disposable consumables.

Cost-Effective

The µPulse consumable chips can be cleaned in place for re-use up to 300 mL of permeate (sample dependent).

Stop Wasting Time Checking on Samples

Simply enter your starting and final volume with optional diafiltration - The μPulse® - TFF System takes care of the rest.

See Your Progress

No need to stop your progress to check on samples.

Control from Anywhere

Remote control and monitoring with our web-based app.

Walk-Away System

Enter your parameters and walk away. Get notified when your sample is ready!

Easy Sample Concentration/Diafiltration (Buffer Exchange, Desalting)

“The µPulse TFF system is a convenient and efficient method for sample concentration during our exosome isolation workflow in conjunction with qEV columns. The software is intuitive, and the instrument provides a rapid method for concentrating lab-scale volumes while maintaining high yields."

Walk-Away Knowing Your Sample is in Good Hands

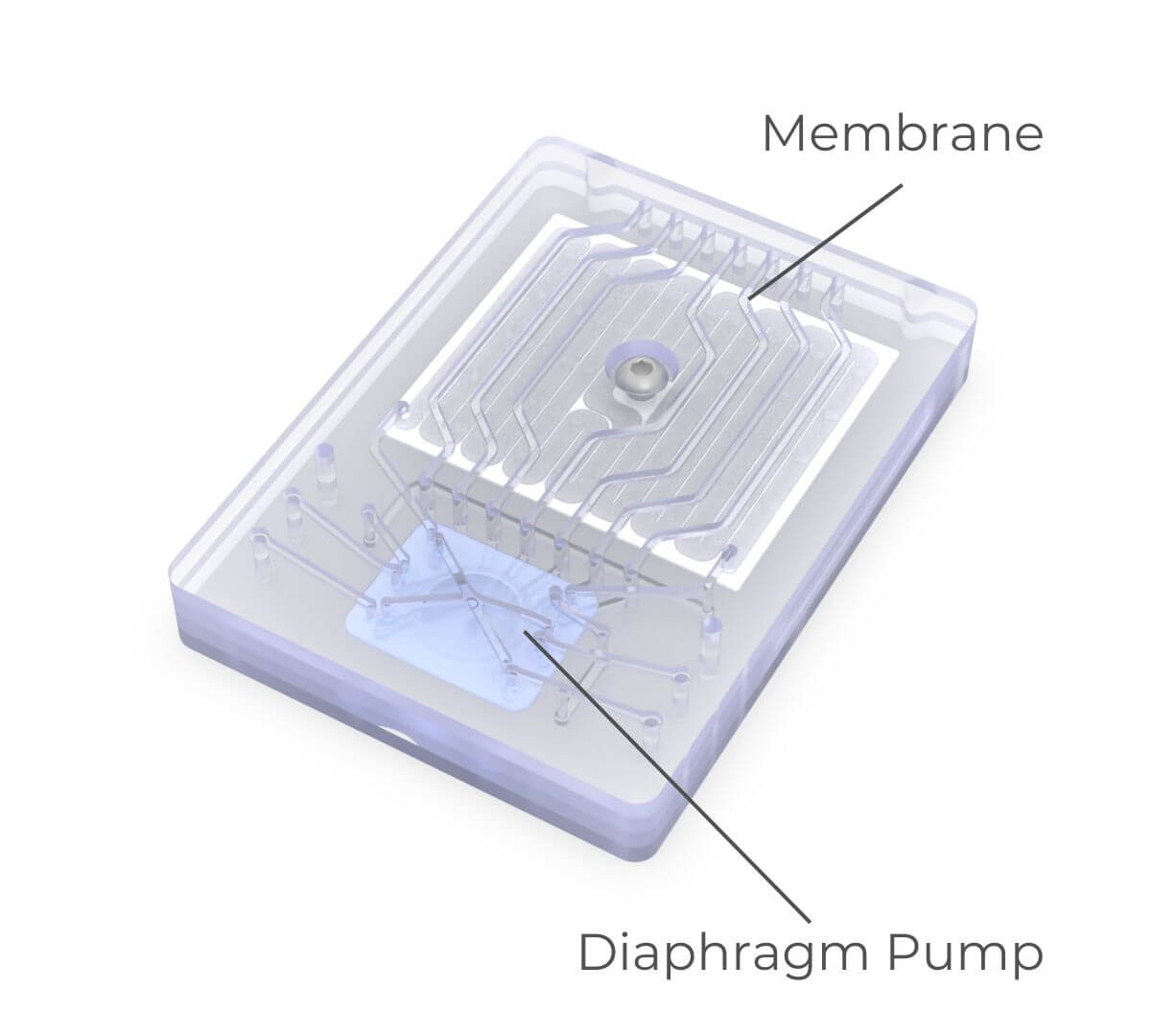

The µPULSE offers the convenience of automated and walk-away sample processing thanks to two key features:

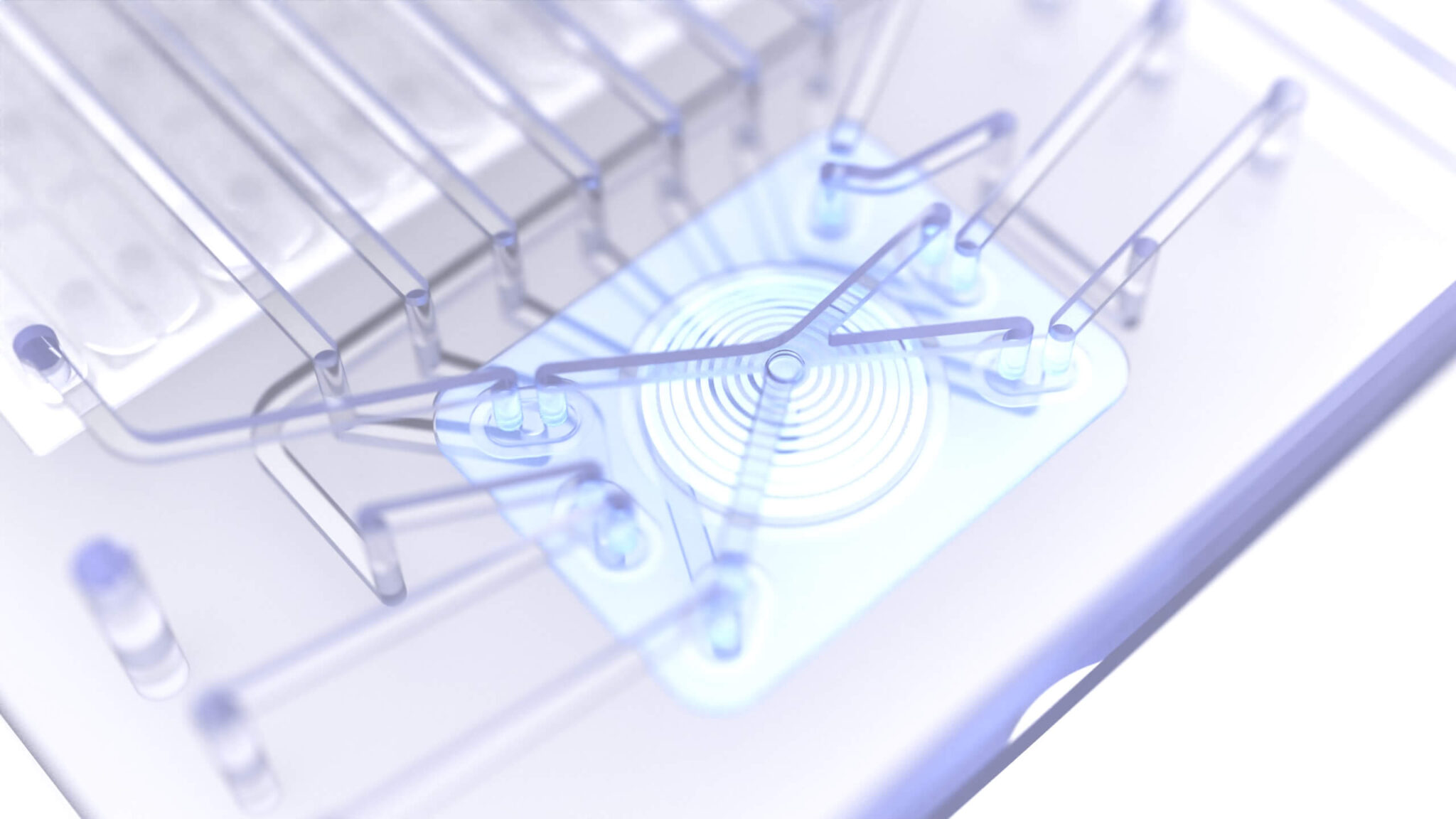

1. Precise Transmembrane Pressure (TMP) Control

Electronically controlled feed and backpressure valves within the filter chip ensure precise TMPs customized to the specific application requirements, avoiding sample damage and membrane fouling.

2. Accurate Volume Tracking

High-precision weight sensors effectively track sample volumes with an accuracy of +/- 0.2 mL, preventing sample over-concentration and ensuring buffer exchange to the desired extent.

“The µPulse unit is both easy to set up and to use. The unit works as it should, being able to filter, and concentrate both crude recombinant fungal and bacterial cultures. The volumes, programmability of desired output in terms of buffer exchange and concentration, make this a superior option to spin filtration units. The disposable filter units are extremely robust and available in convenient cutoff sizes such as 10, 30 and 50 kDa: all relevant cutoffs for our applications."

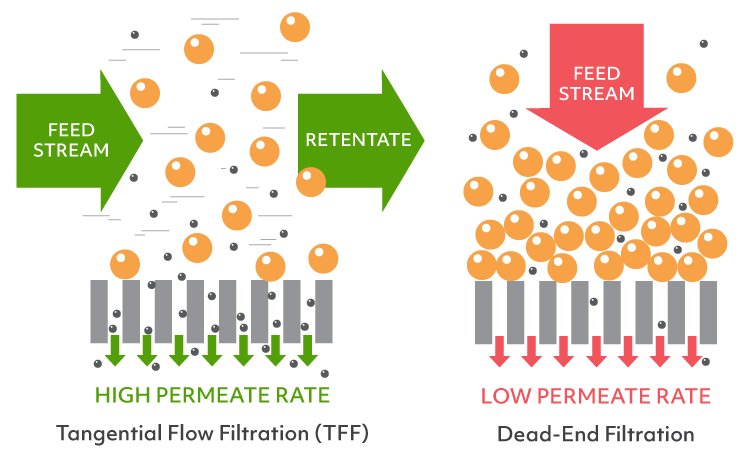

Concentrate Samples Faster with TFF

Unlike centrifuges with traditional dead-end filtration systems, the µPulse prevents a high concentration gradient from forming at the filtration membrane. This means no reduction in the permeate flow rate and increased sample recovery.

With TFF, the concentration process is continuous and gradual allowing for samples to be concentrated up to 4x faster than using dead-end filtration. The exact concentration rate depends on sample size and membrane cutoff size.

The µPulse utilizes a filtration membrane that is 50 - 75% larger than traditional dead-end filtration systems. This larger membrane boasts a higher membrane flux allowing you to concentrate samples faster so you can move on with your research.

"Compared to conventional silica spin columns, which require multiple centrifugations and washes, the µPulse TFF system offers optimized automated purification of mRNA from IVT and Cap1 capping reaction with minimal manual intervention. This allows for faster processing and reduced variability of synthesized and capped IVT-mRNA for both small (~1 mg) and large scale (≥5 mg) synthesis.

The µPulse is particularly ideal for medium to large-scale (≥5 mg) purification of IVT and capped mRNA, ensuring consistency and efficiency in downstream applications."

Versatile for a Broad Range of Scientific Workflows

Efficiently process lipid nanoparticles, liposomes, and polymeric nanoparticles for drug delivery and therapeutic efficacy

Optimize the protein preparative workflow, enabling fast and gentle processes, including concentration, formulation, desalting, and refolding

Ensure gentle and efficient removal of small unconjugated molecules from a variety of crude biomolecular labeling reactions

Simplify in vitro synthesis of RNA, and linear or plasmid DNA, by efficient concentration and buffer exchange using our user-friendly system

Streamline the fast harvesting of cells, extracellular vesicles, enzymes, and Virus-Like Particles (VLPs) while ensuring high product yields and quality

Gently concentrate and exchange buffers for Adeno-associated Virus Vectors (AAVs), bacteriophages, and lentiviruses, preserving their structure for effective applications

Optimize the formulation of DNA, RNA, and polysaccharide vaccines for optimal, stable, and cost-efficient results

“In our laboratory, the µPulse has effectively streamlined exosome isolation from conditioned culture media. The instrument is easy to set up and user-friendly, with built-in and customizable parameters. The miniaturized fluid path, gentle processing, diverse cutoff options, and walk-away functionality, make it particularly well-suited for exosome processing. We gladly endorse the µPulse for lab-scale exosome harvesting."

Easy to Maintain with Disposable Filter Chips

The μPulse - TFF System uses disposable filter chips and transfer tubing. The entire fluid path can be cleaned in place for re-use or discarded for single-use. It can cover a wide variety of sample sizes with 5, 10, 30, 50, 100, and 300 kDa MWCO modified polyethersulfone (mPES) membranes.

Regenerated cellulose (RC) filter chips also come in MWCO sizes of 5, 10, 30, 100, and 300 kDa membranes. The chips are uncharged and have high hydrophilicity, meaning they have exceptional compatibility and are well-suited for applications demanding low non-specific binding. Testing with our industry collaborators has shown higher yields with plasmids, mRNA, LNP's, and some exosomes. RC membranes also have good chemical resistance to solvents, including DMSO.

"We are really pleased with the performance of the µPulse-TFF system, which we have employed in our workflow for purification of Virus-Like Particles (VLPs). The automated system is user-friendly, processes samples quickly and is cost-effective. As a trustworthy and effective method for concentrating the VLPs, I gladly endorse the µPulse-TFF system for use in routine lab-scale processing of VLPs."

Simple Diafiltration: Buffer Exchange, Desalting

Along with concentrating your sample, there is an option for automatic diafiltration to facilitate buffer exchange or desalting processes.

Setup is easy with 15 or 50 mL centrifuge tubes located at the front of the system:

- One tube holds your sample solution

- The other a buffer or any other solution of your choice

The system can be refilled with up to 250 mL of buffer for high diavolume exchanges.

"The µPulse TFF system is a nice compact system for sample diafiltration and concentration. As an efficient alternative to size exclusion chromatography, we have successfully integrated the µPULSE in the process of ADC production (starting volumes between 2 and 50 mL), either for the elimination of residual drug (from the conjugation mix) or for ADC formulation purposes. We are entirely satisfied."

Easy Setup - Monitor from Afar

The µPulse utilizes an intuitive, web-based software application that can be run on the device or via external devices on the same network.

This easy-to-use solution allows the user to set up the starting and desired volumes and concentrations, diafiltration or buffer exchange, and modify advanced settings to optimize concentration for your samples.

Users can remotely monitor the process of their concentration instead of having to manually check.

"The µPulse was easy to use right out of the box and fit our process testing needs quite well. It performed comparatively well against our established TFF process and we were able to translate our older process onto the instrument with minimal issues."

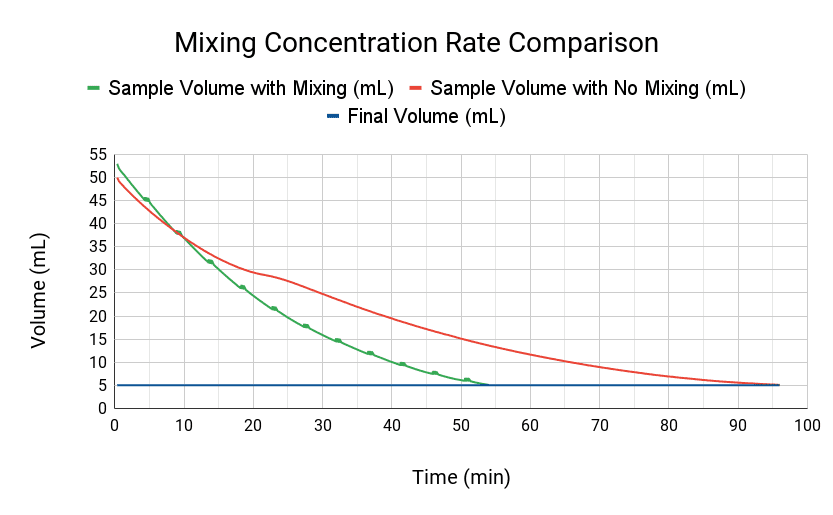

Maintain Sample Uniformity and Consistent Filtration Performance

The µPulse's Mixing Cycle feature helps to maintain sample uniformity and a consistent filtration performance over time. During mixing, the sample is recirculated across the filter medium, preventing localized high concentrations.

The concentration of 500 kDa Blue Dextran at 6 mg/mL with a 50 kDa chip at the default concentration setting and default mixing completed every 4 minutes