About

Sample concentration and buffer exchange are integral to any preparative scale production of recombinant proteins and add a significant amount of time to the overall workflow. On a lab scale, dead-end filtration using centrifugal units is the current standard for sample concentration. However, it is limited by low filtration rates, a lack of scalability, and it is fairly a hands-on method. Alternatively, tangential flow filtration (TFF) offers higher filtration rates but conventional TFF systems have high hold-up volumes, making them unsuitable for labscale applications. To address this issue, Formulatrix has developed the µPulse - a fully automated and miniaturized TFF system, well suited for sample concentration and buffer exchange at lab scale.

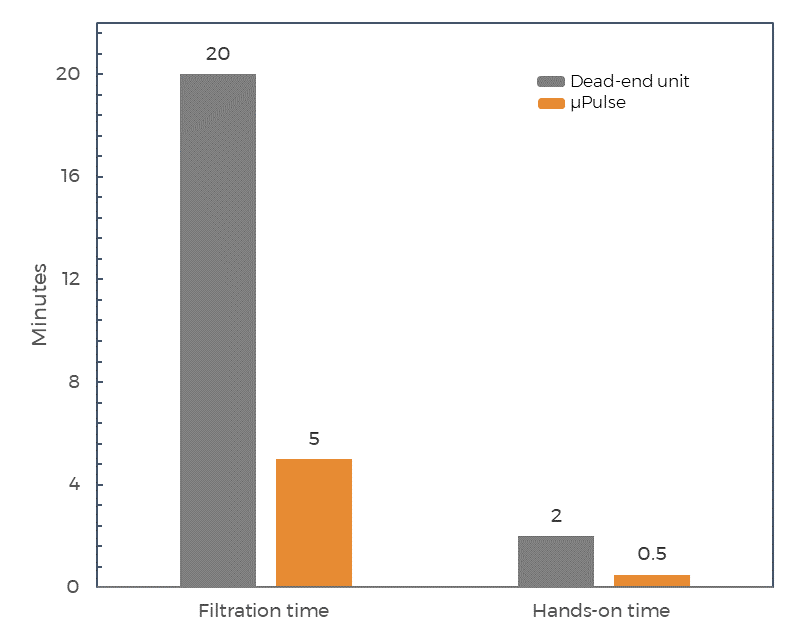

We compared the µPulse with dead-end filtration for concentrating a purified recombinant L-asparaginase produced in Escherichia coli. The µPulse concentrated the L-asparaginase 4 times faster and in a single-step walk-away manner.

Comparison of the filtration and hands-on time required by the dead-end unit and the µPulse.

Furthermore, our results show that the µPulse filter chips can be cleaned in place and reused several times with negligible difference in filtration rates. We conclude that the use of the µPulse TFF system is a fast, scalable, and cost-effective approach for formulation of the purified recombinant proteins, and other biomolecules.