The demand for faster, more efficient biologics development, gene therapy research, and high-throughput screening has created a critical need for advanced sample processing technologies. In today’s workflows, researchers routinely work with:

- Sample volumes under 10 mL

- Dozens of unique conditions

- High-value reagents

- A need for reproducibility and maximum recovery

Dead-end filtration (DEF) units are commonly used for concentrating small-volume samples and exchanging buffers. While engineered for low volumes, they require manual setup and processing — and when scaled to high throughput, labs must run several DEF devices in parallel, increasing hands-on time and variability. Additionally, direct-flow in DEF leads to low filtration rates, rapid membrane fouling, and the risk of sample loss due to aggregation. On the other hand, tangential flow filtration (TFF) offers high filtration rates, and scalability. But conventional TFF systems aren’t built for small volumes. Their bulky flow paths, manual setup, and high hold-up volumes make them incompatible with workflows involving volumes ranging from submilliliters to a few milliliters.

The aµtoPulse - High-throughput TFF System

The aµtoPulse® is an automated, high-throughput TFF system engineered for ultra-low volume workflows, offering the world’s lowest hold-up volume with up to 100% recovery.

Built on insights from our µPulse® users, it advances our patented millifluidic TFF technology with enhanced automation, scalability, and throughput. The system enables fully automated, parallel sample processing while maintaining individual sample process control.

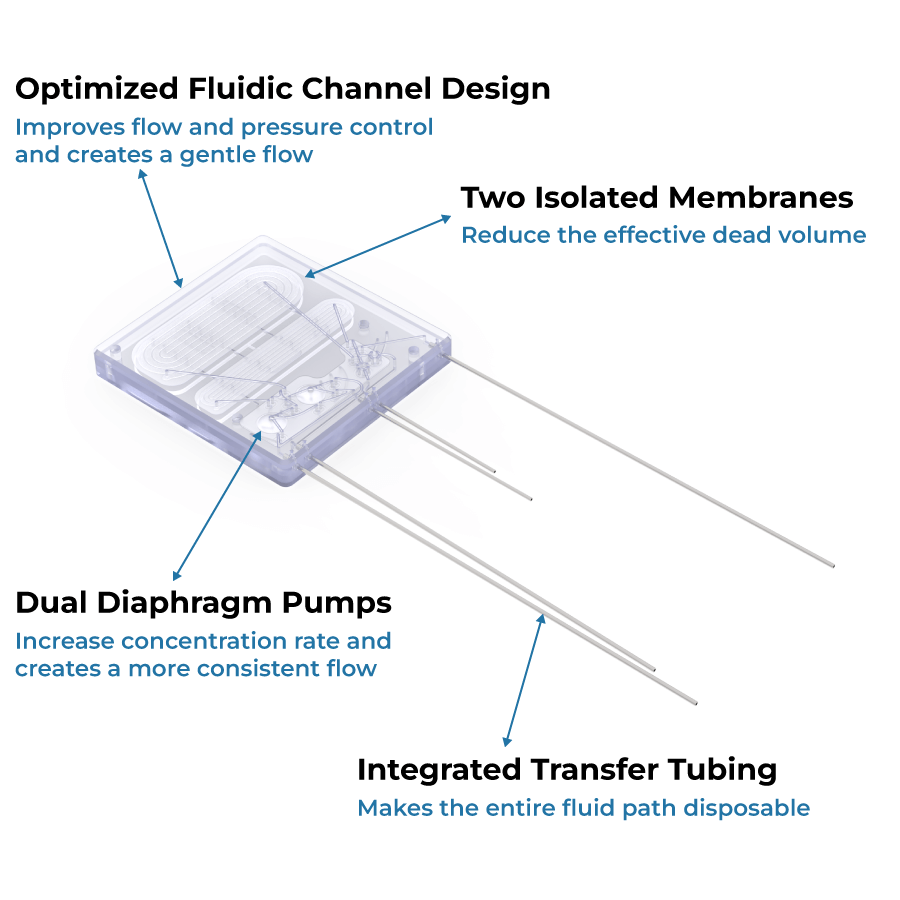

The functional unit of the aµtoPulse is the filter chip, which is engineered to meet the needs of the scientific community, delivering unparalleled speed, efficiency, and control for the most demanding low-volume workflows.

Key Features of the aµtoPulse Filter Chip

Designed to streamline and accelerate the filtration process, the aµtoPulse filter chip incorporates targeted features that enhance TFF efficiency from setup to recovery.

Double Diaphragm for Faster Processing

At the heart of the aµtoPulse chip are two diaphragm pumps that work in a synchronized fashion—while one expels fluid, the other refills. This eliminates downtime, enabling continuous flow and a concentration speed that is more than 1.5 times faster than that of single-diaphragm µPulse chips.

Lowest Hold-Up Volume in Industry

The aµtoPulse chip offers two distinct membrane pathways to suit a broader range of sample volumes and applications.

- Small membrane area: 3.5 cm²

- Large membrane: 8.5 cm²

For high-volume samples, both membranes (with 12 cm² filtration area) work in parallel, enabling high-flux concentration. To reach ultra-low final volumes, the system intelligently transfers the sample to the smaller membrane. This selective routing allows the aµtoPulse chip to consistently reach a final volume of just 250 µL, the lowest hold-up volume ever achieved in TFF.

Sensitive Handling

The aµtoPulse chip features enhanced fluidic control through an innovative µPumping technique, enabling precise volume and flow control. Integrated channels allow reliable priming and sample recovery for all types of samples, including high-viscosity fluids. In addition, pressure-based flow control on the feed and retentate paths allows for operation across a range of flow rates and pressures.

Integrated Transfer Tubing for Contamination-Free, Flexible Volume Processing

The re-invented disposable filter chips integrate stainless steel transfer tubing to create an entirely consumable fluid path that prevents cross-contamination. For protocols requiring chip reuse, the tubing is fully compatible with the aµtoPulse’s automated Cleaning-In-Place (CIP) system. With dedicated cleaning stations connected to external reservoirs, the chips can be reliably cleaned between runs, thereby extending the utility of consumables without compromising performance.

The transfer tubing design enables sample processing from various tube sizes. The left set of transfer tubes connects to 15 mL or 50 mL tubes for sample input. The middle one is designed for low-volume 1.5 mL tubes, and is essential for achieving ultra-low final volumes down to 250 µL. The right part of the transfer tubing is used to transfer the buffer or an extra sample, enhancing workflow flexibility.

Versatile Membrane Compatibility and Wide MWCO Range

The filter chips are designed to handle a broad range of buffers and solvents, making them suitable for diverse applications. The modified polyethersulfone (mPES) and regenerated cellulose (RC) membranes offer excellent resistance to harsh chemicals while ensuring high recovery rates. Additionally, the filter chips support a variety of molecular weight cutoffs (MWCOs). mPES membranes are available in pore sizes ranging from 5 to 300 kDa, while RC options include 5 to 100 kDa MWCO membranes, providing flexibility for various experimental needs.

| Feature | RC | mPES |

|---|---|---|

| Pore Structure | Symmetric | Asymmetric |

| Temperature Tolerance | Low to Moderate | High |

| pH Resistance | Moderate Tolerance to Extreme pHs | High Tolerance to Extreme pHs |

| Chemical Compatibility | High | Moderate |

| Charge | Uncharged | The Sulfone Group is Negatively Charged at pH 7.0 |

| Hydrophilicity | High | Moderate |

| Thermal Stability | Lower Compared to PES | High Thermal Resistance |

| Fouling | Very Low | Low |

| Protein Binding | Very Low | Low |

| Extractables | Very Low | Low |

| Flux Rate | Moderate | High |

| Suitability | Preferred for Charged Proteins, Nucleic Acids, and LNPs | Preferred for Uncharged Biomolecules |

Versatile for a Broad Range of Scientific Workflows

Efficiently process lipid nanoparticles, liposomes, and polymeric nanoparticles for drug delivery and therapeutic efficacy

Optimize the protein preparative workflow, enabling fast and gentle processes, including concentration, formulation, desalting, and refolding

Ensure gentle and efficient removal of small unconjugated molecules from a variety of crude biomolecular labeling reactions

Simplify in vitro synthesis of RNA, and linear or plasmid DNA, by efficient concentration and buffer exchange using our user-friendly system

Streamline the fast harvesting of cells, extracellular vesicles, enzymes, and Virus-Like Particles (VLPs) while ensuring high product yields and quality

Gently concentrate and exchange buffers for Adeno-associated Virus Vectors (AAVs), bacteriophages, and lentiviruses, preserving their structure for effective applications

Optimize the formulation of DNA, RNA, and polysaccharide vaccines for optimal, stable, and cost-efficient results