Considerations for the Automation of Sequencing Workflows

Why should I automate my sequencing workflow?

Figure 1. FORMULATRIX® aims to help researchers sequence more efficiently so that they can generate more meaningful data

Next Generation Sequencing (NGS) workflow efficiencies allow researchers to reallocate funding to strengthen the power of their analysis. Usually, this involves investing in more powerful analysis tools or increasing sample throughput. Especially in single-cell RNA-sequencing, data from larger sample sizes provide more accurate and reproducible analysis of gene expression.

The benefits of automation come at a cost

The reasons to automate sequencing workflows are compelling and, at this point, the message coming from automated liquid handling vendors is mainstream:

“Automation facilitates the generation of more reproducible data and allows researchers to focus time on more valuable tasks like analyzing data or designing the next series of experiments.”

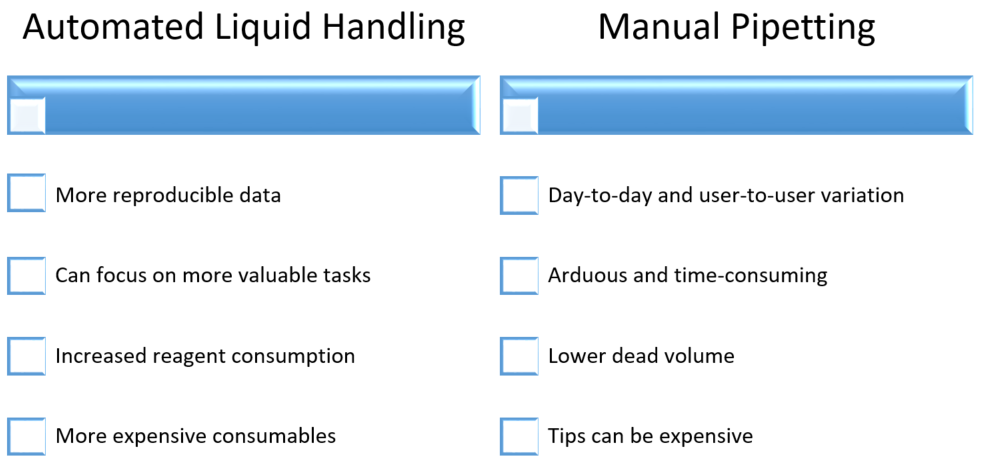

However, these benefits come at a cost. Automation can require a higher dead volume and more expensive consumables than manual methods. Especially in genomics, where the high cost of reagents can be a limiting factor in throughput, researchers should do their due diligence to find the most efficient automated solution for their genetic analysis.

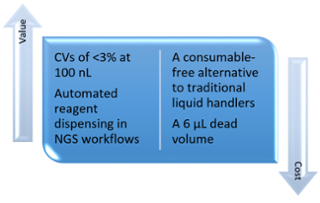

Figure 2. Cost/benefit analysis of automated and manual liquid handling – an ideal solution would maximize reproducibility and save time while decreasing costs associated with tips and reagent dead volume

Quantification of costs for manual and automated workflows

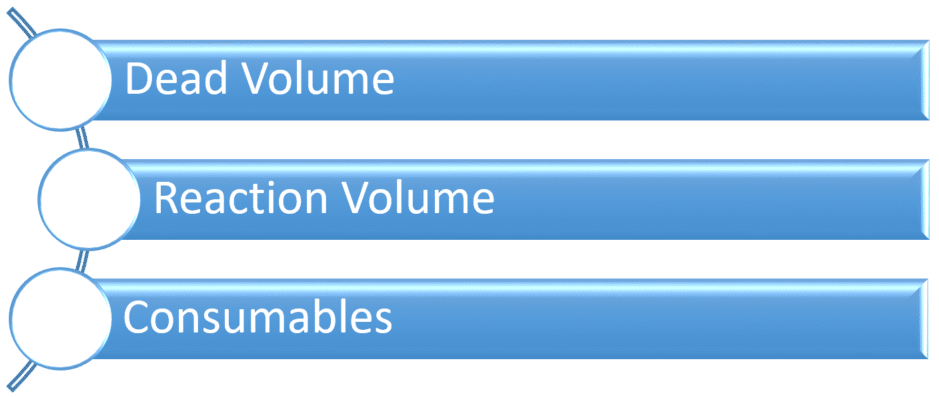

Figure 3. Costs associated with genomics workflows - long term cost of ownership varies depending on the approach to liquid handling for sequencing libary preparation.

When researching automated liquid handling solutions, researchers can quantify the costs associated with dead volumes, reaction volumes, and consumables for each alternative. For instance, a traditional automated liquid handler will require a minimum dead volume of 30 µL. However, in order to perform a given application in a reasonable amount of time, even more reagent will be necessary to accommodate a multichannel approach.

From reverse transcription through library preparation and quality control, reagent costs add up quickly. In order to maximize the use of every microliter, scientists should look to minimize both dead volumes and reaction volumes.

Ensuring that benefits outweigh costs in the long term

Researchers should always evaluate automated liquid handling solutions in a logical way, accounting for the long term costs of dead volumes, reaction volumes, and tip consumption.

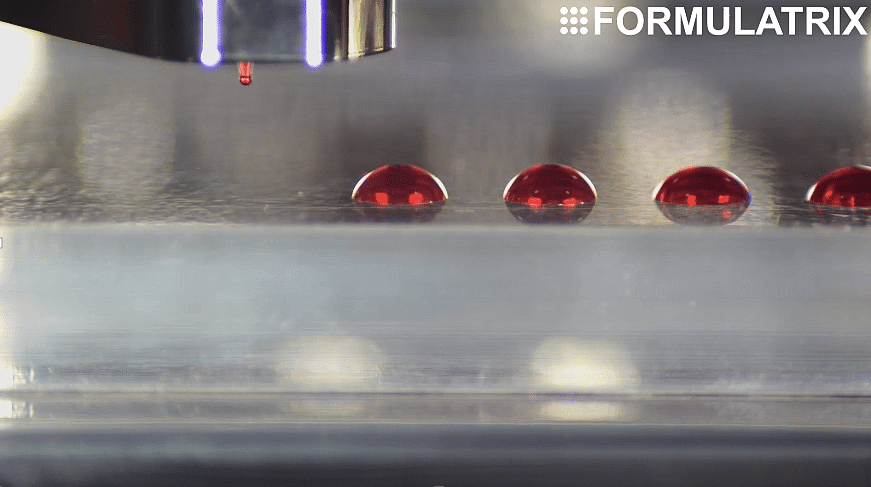

Luckily for researchers everywhere, miniaturization of reaction volumes is entering the mainstream. Scientists routinely show that they can generate quality libraries, achieving sufficient gene coverage and reads when using ½ and even ¼ reaction volumes.

When considering a solution for NGS automation, it is vital that a given liquid handler can accurately and precisely achieve the volumes necessary for such scaled down workflows. Otherwise, a user may not be able to take advantage of this trend.

Figure 4. Some miniaturized reactions call for dispensing down to 0.5 µL

A novel solution for contemporary genomics

Figure 5. The MANTIS is a balanced solution offering a high value at a reduced cost compared to manual pipetting and traditional automated solutions

The high cost of sequencing reagents and the call for more reproducible data in translational genomics research require a unique approach to automated liquid handling. An ideal solution would maximize reproducibility and save time while decreasing costs associated with tips and reagent consumption.

The MANTIS® , a microfluidic liquid handler, provides researchers with a solution for the automation of sequencing experiments that provides the perfect balance between value and cost.