Design of Experiment (DoE) is a powerful approach for optimizing experiments with multiple factors. It allows researchers to test many conditions simultaneously, revealing how these factors interact, all while reducing the total number of experiments needed. This saves time, labor, and materials. However, due to challenges in implementation and limitations of existing liquid handling systems, DoE has yet to be widely adopted.

The Tempest Liquid Dispenser from Formulatrix addresses the liquid handling limitations hindering DoE adoption. It uses non-contact, tipless dispensing to eliminate contamination risks, reduce consumable costs and environmental waste, and increase experiment throughput. This technology allows precise dispensing at low volumes with minimal waste (dead volume) to conserve reagents. Features like recirculation and continuous flow also maintain reagent consistency, such as cells and beads, and enable recovery.

The Synthace Software Platform is designed to streamline the implementation DoE workflows. Unlike traditional statistical software or spreadsheet-based experiment design, Synthace intuitively guides users to implement multifactorial experiment designs, test multiple conditions simultaneously, identify key interactions between factors, and interface directly with automation equipment to manage experimental planning and automatically generate execution instructions.

For research teams working in small and large-molecule drug discovery looking to expedite their timelines and produce optimized, high-performing assays – Synthace’s innovative experiment software paired with the high-precision Formulatrix dispensers, such as the Tempest, enables users to develop experiments that produce unparalleled insights in assay development.

Learn how this powerful combination allows scientists to leverage DoE easily and efficiently, accelerating their research.

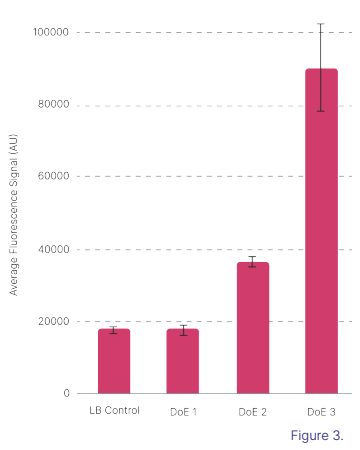

Optimization of 12 growth media factors resulting in a 5-fold average increase in eGFP production in 3 weeks. A custom screening design was used to generate a statistical profile of the contribution of 11 factors to eGFP production in the first iteration (DOE 1). Key factors contributing to the highest yields were identified from DoE 1 and then modulated in the second iteration (DOE 2). DOE 2 had the effect of increasing the total eGFP yield by 2-fold on average over the LB growth medium control. The third and final iteration (DoE 3) focused on critical process parameters. Overall, results demonstrate a 5-fold increase in eGFP production over the LB control.

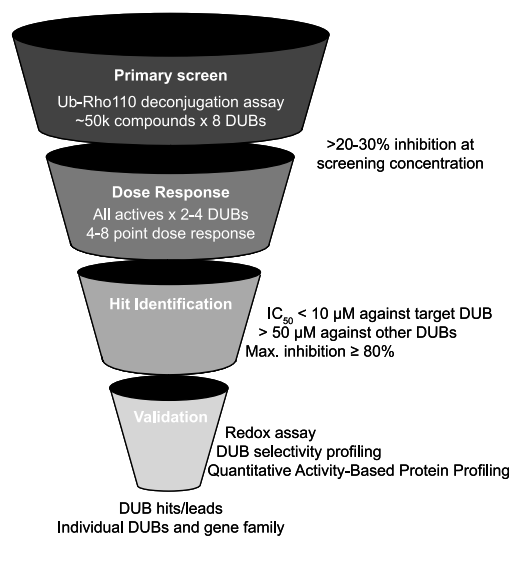

For optimizing the buffer concentration to be used in the primary screen for this High Throughput Screening (HTS) assay, JMP software was used for DoE and Tempest was used to dispense all buffer components.

About the Speakers

Khalid Elawad is a Senior Product Commercialization Manager at Synthace. He works with scientists and engineers at the interface of innovative lab software and powerful experiments. Khalid explores how Synthace software can unlock new potential for the use of automation in research and process development by eliminating the barriers associated with complicated experimental design and planning. Prior to joining Synthace, Khalid earned his Master's degree in biomaterials engineering, studying the use of biopolymers as in-vitro cell matrices, and worked as a research scientist optimizing automated diagnostics assays with Becton Dickinson.

Talha Bin Rahat, the Application Scientist at FORMULATRIX, holds a master's degree in Healthcare Biotechnology. With a strong background in Forensic Biology, Molecular Biology, Biotechnology, and Virology, he has over three years of lab experience following ISO 17025 principles. Additionally, he has six months of field experience as a crime and death scene investigator.