The Low-Volume Bottleneck:

Why Your Lab Needs High-Throughput Automated TFF

Modern biological research is a story of increasing complexity. Scientists are working with more variables than ever before; from small molecule screening in drug discovery, to process development for therapeutic antibody, exosome, and virus production. Not only are the number of experimental conditions exploding, but the sample volumes themselves are shrinking.

This creates a significant challenge: your science is becoming more sophisticated, but the tools available for critical everyday steps of sample ultrafiltration and diafiltration (UF/DF) haven't kept pace. If you're working with dozens of unique, high-value samples under 10 mL, you’re likely feeling the strain of this process bottleneck.

The Gaps in Current Ultrafiltration Methods

For decades, labs have relied on two main methods for ultrafiltration, each with a critical flaw for modern, low-volume, high-throughput workflows.

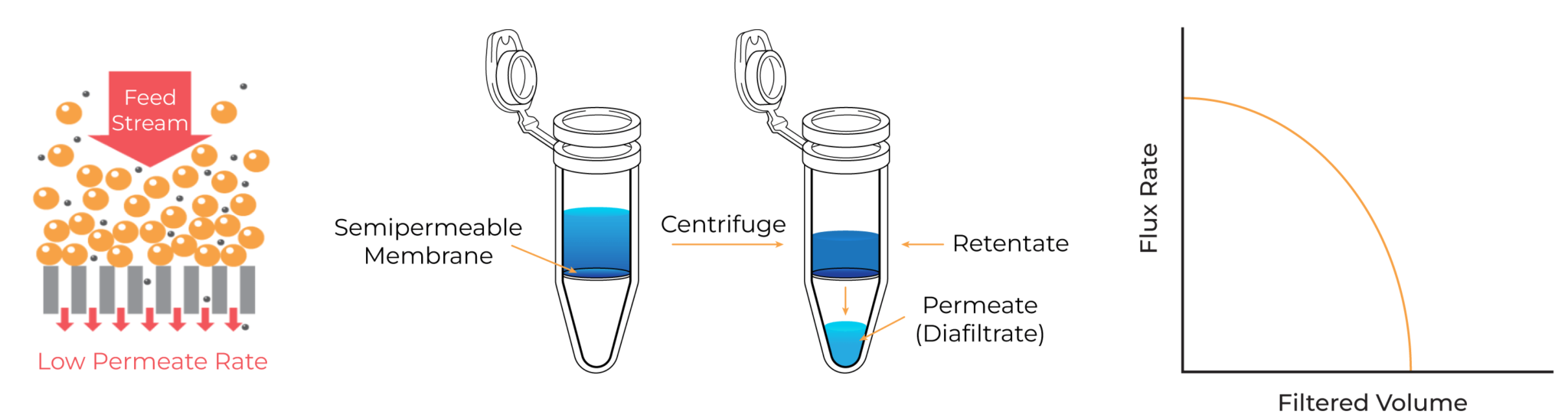

The Dead-End Filtration (DEF) Trap

Centrifugal devices are the default for many labs. They are simple, disposable, and perfect for a single, low-volume sample. The problem arises when "a single sample" becomes 24, 48, or more. Suddenly, your day is consumed by a highly manual, repetitive process:

- Slow Filtration Rates: In DEF, the particles being filtered out accumulate directly on the surface of the filter, forming a dense layer called filter cake. This cake clogs the membrane pores and adds significant resistance to the liquid flow.

- Sample Loss: The high concentration of molecules pressed directly onto the membrane surface, combined with the shear forces of centrifugation, can cause irreversible sample aggregation and denaturation. This results in lower yields of active, functional products.

- Massive Hands-On Time: Repetitive pipetting, balancing centrifuges, and carefully recovering samples from multiple devices turn a multi-condition experiment into a full day of tedious labor.

- Process Variability: Manual handling introduces inconsistency. Slight variations in timing, pipetting technique, or incomplete recovery can significantly impact your results, making it difficult to compare samples confidently.

While DEF units are useful, they simply don't scale. They turn high-throughput experiments into low-throughput processes.

Dead-End Filtration

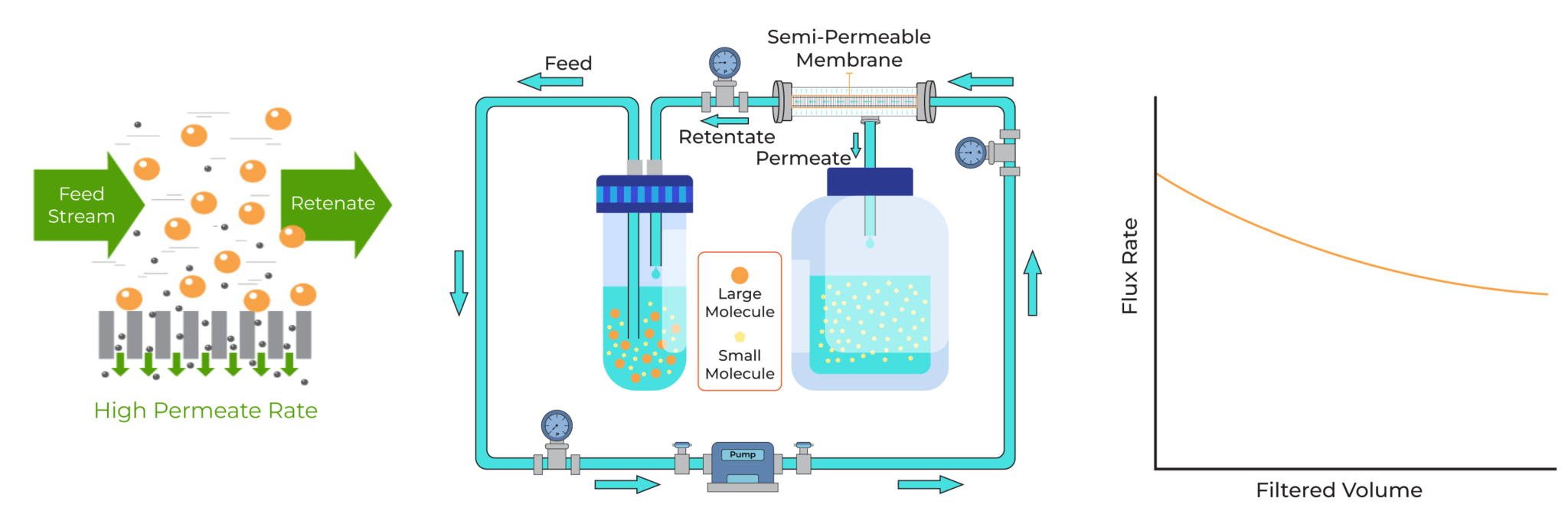

The Conventional Tangential Flow Filtration (TFF) Misfit

On the other end of the spectrum is traditional TFF. It’s the gold standard for large-volume processing due to its higher filtration rates, gentle nature, and scalability. However, conventional TFF systems are not designed for the microliter-to-milliliter world:

- Prohibitive Hold-Up Volumes: The flow paths in these systems are bulky, leading to hold-up (or dead-leg) volumes of many milliliters. Trying to process a 5 mL sample in such a system means losing a considerable fraction of your precious material.

- Complex Setup: Conventional TFF systems often require manual assembly of tubing, cassettes, and pumps, making it tedious to run dozens of unique samples in parallel.

This leaves a massive gap for scientists who need the gentle, efficient processing of TFF but at the low volumes typical of DEF.

Tangential Flow Filtration

Bridging the Gap: The aµtoPulse® - TFF Instrument

What if you could combine the low-volume suitability of a centrifugal device with the automated, high-throughput, and gentle efficiency of TFF? This is precisely the gap the Formulatrix aµtoPulse TFF Instrument is engineered to fill.

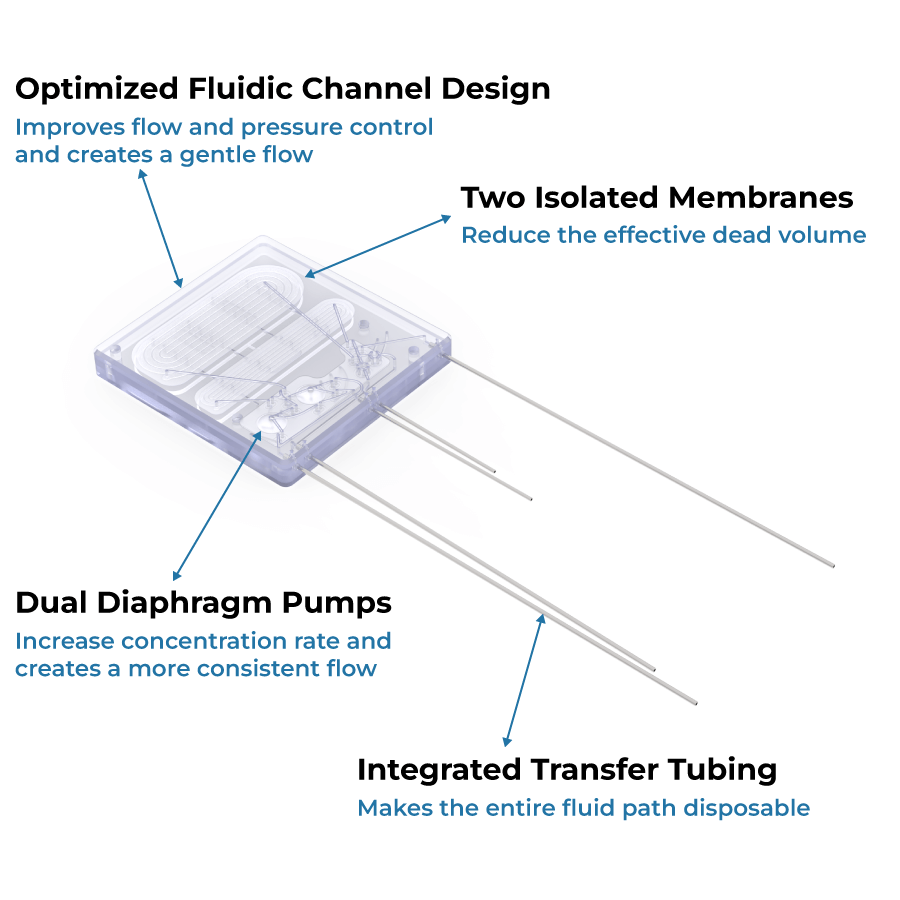

The aµtoPulse is an automated, high-throughput TFF instrument engineered for ultra-low volume workflows, offering the world’s lowest hold-up volume that’s fully recoverable. Built on insights from our µPulse® users, it advances our patented millifluidic TFF technology with enhanced automation, scalability, and throughput. The instrument enables fully automated, parallel sample processing while maintaining individual sample process control. It achieves this through its core innovation: the aµtoPulse filter chip.

What aµtoPulse Offers Your Workflow

Elimination of Sample Loss

The fear of losing a precious sample is over. The aµtoPulse chip’s intelligent dual-membrane design (using a combined 12 cm2 area for bulk concentration and a smaller 3.5 cm2 area for final recovery) enables it to keep the hold-up volume as low as 180 µL (250 µL with tube) consistently. Recover every drop automatically using customizable air and buffer rinse cycles.

High-Throughput

The aµtoPulse is engineered from the ground up for high throughput. It allows you to process up to 54 samples in a single run, with parallel processing of up to four samples simultaneously. Critically, each sample maintains independent process control, giving you the flexibility to test different conditions at once.

Faster Filtration and Unattended Operation

The two diaphragm pumps in the chip work in a synchronized manner— while one expels fluid, the other refills. This allows continuous flow and filtration rates, 1.5x faster than single-diaphragm µPulse chips. The automated volume sensing frees you to walk away and focus on the next stage of your research, not on nursing your samples.

Sensitive Handling

The aµtoPulse chip features enhanced fluidic control through an innovative µPumping technique, enabling precise volume and flow control. Integrated channels allow reliable priming and sample recovery for all types of samples, including high-viscosity fluids. In addition, pressure-based flow control on the feed and retentate paths allows for operation across a range of flow rates and pressures.

A Flexible Workflow for Every Need

The aµtoPulse instrument is designed for the real world, where protocols and samples vary.

- Sample Isolation & Decontamination/Sanitation: The chip's integrated tubing creates an entirely consumable fluid path, containing your sample to a single unit for easy disposal and eliminating cross-contamination risk. For workflows where re-use is desired, the chips can be automatically re-cleaned by the instrument’s Cleaning-In-Place (CIP) station.

- Versatile Sample Formats: The instrument can accommodate standard 15 mL and 50 mL tubes for input and uses a dedicated 1.5 mL microtube for precision recovery of the final concentrate.

- Complete Process Control: Customize your UF/DF process with complete control over each step. Find the most efficient results by buffer exchanging before or after concentrating, or anywhere in between.

- Broad Application Range: With a wide variety of membrane materials (mPES, RC) and molecular weight cutoffs (3 kDa to 300 kDa), the instrument is equipped to handle nearly any biomolecule you work with.

Reclaim Your Time, Maximize Your Science

High-throughput low-volume UF/DF no longer has to be your workflow bottleneck. By automating these critical steps, the aµtoPulse eliminates hours of manual labor, minimizes sample loss, and dramatically improves reproducibility. Have the confidence to expand the scope of your experiments knowing that your sample preparation can keep pace with your science.