Assay development and optimization are critical processes in scientific research and industrial applications. Their significance spans across multiple fields, including diagnostics, drug discovery, genomics, proteomics, and quality control. Well-optimized assays improve the workflow productivity by ensuring specificity, reaction miniaturization, and faster results.

The One-Factor-At-a-Time (OFAT) approach for assay development and optimization, while straightforward, requires a higher number of experiments, consuming more reagents and time. It also fails to identify significant interactions between factors, leading to suboptimal results.

In contrast, Design of Experiments (DoE) enables systematic identification and optimization of assay parameters. It not only saves time and resources but also provides deeper insights into interactions between variables with fewer experiments. However, DoE's complexity arises from the need to prepare multiple reagent combinations simultaneously.

Liquid handling is central to executing either OFAT or DoE, and presents several challenges such as precision, time and cost efficiency, throughput, and reproducibility. Manual pipetting, while cost-effective for simple workflows, is limited by low precision, throughput, and reproducibility, especially with small volumes. Moreover, it is not suited for implementing complex DoE protocols.

Stages in assay development and optimization

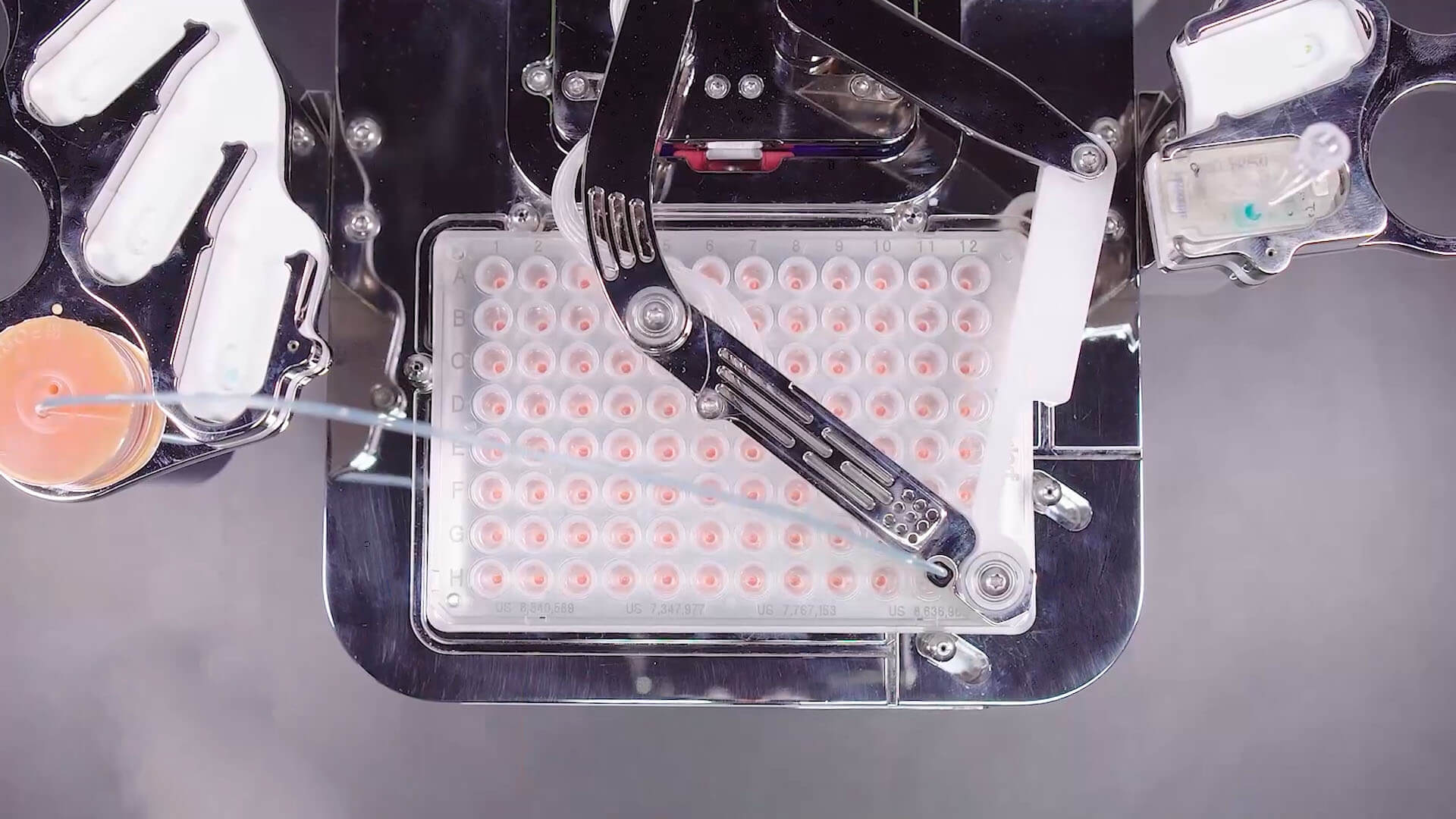

In contrast, automated liquid handling (ALH) offers high-throughput assay development and optimization, and reduces processing time and ensures reproducibility by eliminating operator variability. ALH systems also facilitate efficient translation of complex DoE protocols by providing precise control over experimental variables. These capabilities make ALH an indispensable tool for cost-effective and reproducible assay development and optimization.

Formulatrix ALH for Assay Development and Optimization

Formulatrix’s ALH systems — including the Mantis® and Tempest® tipless dispensers, and the F.A.S.T.TM and FLO i8® PD liquid handlers — provide precise and accurate small-volume dispenses that help ensure consistent results across experiments. Our ALH systems feature user-friendly programming interfaces that allow researchers to easily define and execute complex DoE protocols. With API integration, our systems enable connectivity with other laboratory instruments and software, thus supporting comprehensive workflow automation and data synchronization.

Formulatrix Liquid Dispensers

Formulatrix Liquid Handlers

| Liquid Handling Features | Mantis | Tempest | F.A.S.T. | FLO i8 PD |

|---|---|---|---|---|

| Technology | Microdiaphragm pump | Microdiaphragm pump | Positive displacement | Positive displacement |

| Precision (CV) | < 2% at 100 nL | < 3% at 200 nL | < 5% at 100 nL | < 5% at 0.5 µL |

| Liquid Class Compatibility | Up to 25 cP | Up to 20 cP | Liquid class agnostic | Liquid class agnostic |

| Throughput | Low to medium | Medium to high | Medium to high | Low to medium |

| Contamination Risk Mitigation | Non-contact dispensing with isolated fluid path | Non-contact dispensing with isolated fluid path | Disposable tips | Disposable tips |

| Hold-Up Volume (µL) | ~6 | ~48 (per chip) | Close to zero | Close to zero |

| Volume Range | 100 nL-∞ | 200 nL-∞ | 100 nL- 13µL | 200* nL- 1 mL |

*200 nL for non-contact dispensing and 500 nL for contact transfer

Table: Formulatrix ALH systems

Webinars

Discover how the F.A.S.T. liquid handler facilitates the quantification of over 5,000 proteins from as little as three microliters of sample.

Application Notes

Mantis facilitates high-combinatorial screening for media optimization with enhanced precision through its innovative tipless dispensing technology.

Experience how the Tempest drives down the cost of assay reagents by 60% with miniaturization while generating high-quality screening data.