The formation of the Structural Genomics Consortium in 2004 has significantly increased the number of structures deposited to Protein Data Bank (PDB) per year for two reasons: the advent of a large group of researchers focused on solving and depositing structures and the creation of the automation space for crystallization screening. It would not be possible without automated imagers as routine inspection of crystallization experiments is very time-consuming. However, specialized liquid handlers capable of dispensing sub-microliter volumes were, and remain, the absolute requirement for accelerating crystallization screening.

These liquid handlers are frequently called drop setters and allow researchers to set up the experiments faster, but more importantly, to set up more screens with the same amount of sample due to the reliable low-volume performance of the instruments. Unfortunately, lower volume crystallization experiments are very sensitive to evaporation, which can be countered by either the instrument speed, which can not be increased without other drawbacks, or by the addition of humidity control.

Active Humidity Control Testing

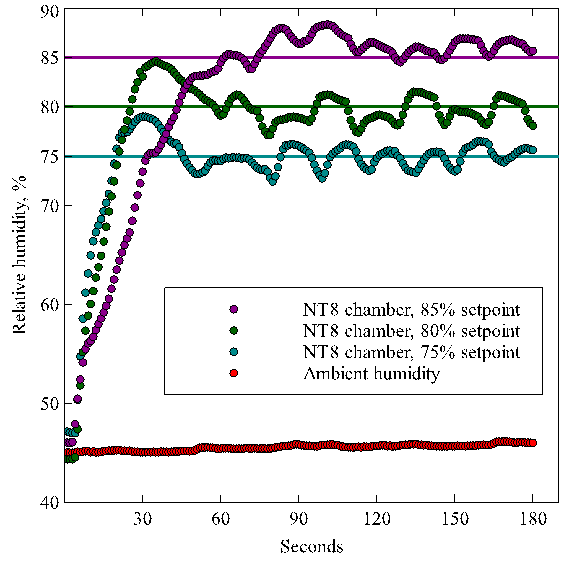

We have previously reported the crucial part humidity control plays in crystallization screening (Friedlander et al., Acta Cryst. (2017). A73, a208). The NT8 takes humidity control to the next level with three independently controlled transducers responding in a proportional manner to the humidity level inside the NT8 chamber. As seen in the charts, NT8 can achieve setpoints in under one minute using the standard settings and maintain the humidity level with minimal fluctuation. Thus, it eliminates reproducibility concerns relating to atmospheric conditions, time of year, geographic location of the lab, and so on.

Precision of Drop Setting

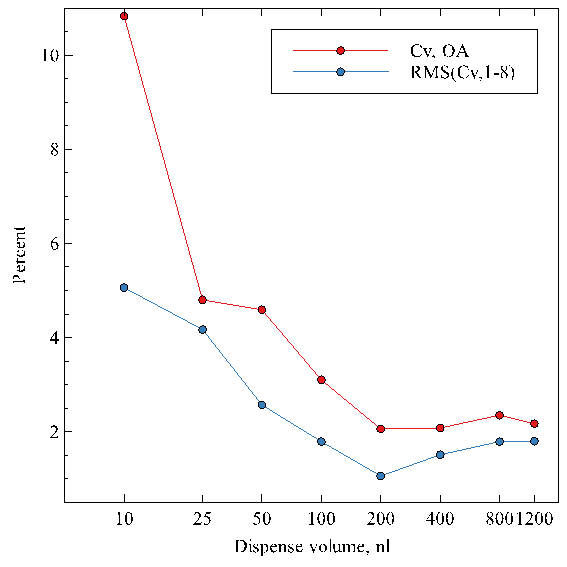

Here we present the NT8’s liquid handling performance highlighting the single-digit relative imprecision across the typical usage scenarios. NT8 exhibits solid wet dispense performance of sub-3% Cv, OA over typical volumes used in crystallization screening (100 nL and up). At the same time, it is capable of wet dispenses of much lower volumes of 10-50 nL that find use in fragment cocktail/additive screening as well as micro-seeding experiments.

The NT8 is one of the most recent automation solutions to join the ranks of the drop setters. The system features a modular head construction, allowing for a combination of Low Volume (LV) (=<1.5 uL), High Volume (HV) (20-200 uL), and Lipidic Cubic Phase (LCP) (as low as 0.03 uL) sub-assemblies. The LV head uses proprietary tips that can be automatically washed and reused to reduce the consumable cost to the researcher and environmental impact. In contrast, the other two heads use commercially-available consumables. The NT8 also includes a built-in LCP mixer and the most advanced humidity control with a proportional response to prevent evaporation.

Don't Worry about topping off the humidifiers

The NT8 uses a minute amount of water while maintaining a relative humidity of 85%. This coupled with a 5-gallon reservoir means that you won't run out of humidification during a dispense or need to refill the deionized water very often.

Materials and Methods

NT8 Active Humidity Control Testing

The NT8 was placed in a closed room equilibrated at 45% relative humidity overnight. Data was collected using two Sensiron® SHT31 Smart Gadgets logging humidity at 1-second intervals. One SHT31 gadget was placed on the bench outside of the NT8, the other in Plate Station 1. The NT8 enclosure was closed and a simple plate dispense was executed on Plate station 2, mimicking typical operating conditions.

NT8 Low Volume Head Precision Testing

Precision (CV) testing was conducted as described in the “TEMPEST® Liquid Handler Installation and Operation Qualification” document, available on-demand from FORMULATRIX®. The three necessary modifications were made: 1) making a 3110 Au working dye to cover the range between 20 and 200 nL; 2) making 6220 Au working dye for 10 nL dispense; 3) use of Brand® 781602 plates as a drop-in replacement for Corning® 3631/3632 plates

In brief, first, MANTIS® Continuous Flow was used to fill the test plates with 100 ul of diluent. Next, the NT8 was used to transfer varying volumes of fluorescein from the protein block to test plates. The plate was then transferred back to the Mantis for the second 100 ul diluent addition. After mixing and spinning the plate down, the optical densities were measured using a BMG Spectrostar Nano® plate reader. A single 96-well plate was used for any given volume. Overall Cv (Cv, OA) and RMS of per-channel CV (RMS(Cv,1-8) were calculated per ISO IWA 15:2015(E)

Conclusion

Based on the data presented, we conclude that the NT8 is the tool of choice for conducting highly-reproducible crystallization screening by eliminating the ambient humidity as well as drop setting volumetric performance from the equation. NT8’s extreme low-volume performance, while less precise, is still going to be a benefit for micro-seeding, additive, and cocktail screening.