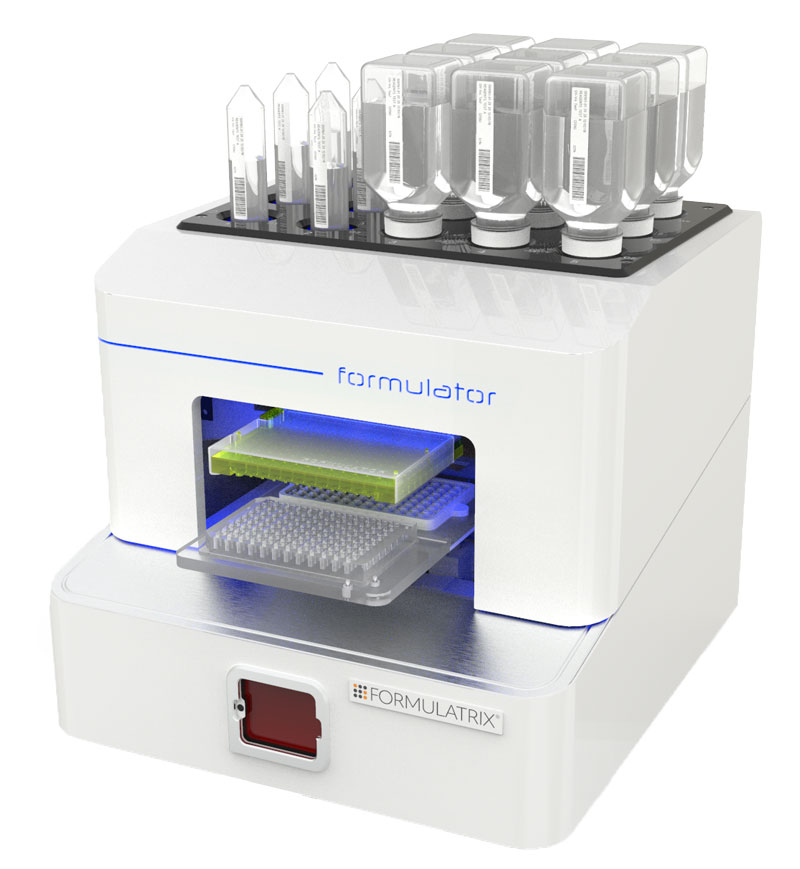

Build Formulation Screens with Ease

The FORMULATOR® - Protein Formulation Screen Builder is a next-generation liquid handler that uses patented microfluidic technology to dispense up to 34 different ingredients. A 96-nozzle dispensing chip can dispense any volume of any ingredient of any viscosity into any well.

Flexible Liquid Dispensing

- Low volumes, down to 200 nL with no upper limit

- Dispense a 100 μL, 3-ingredient, 96-well formulation grid in 2.7 mins

- Supports all microplate types

Easy Operation

- Integrated barcode scanner automatically loads experiment and ingredient data

- Bottle sensors know where ingredients are located

- Design, Barcode, Scan, and Run

No Consumables Needed

- Reduce your lab’s costs and environmental impact

Closed Ingredient Containers

- Prevents evaporation, contamination, and noxious fumes from escaping

Dispense Viscous and Non-Viscous Ingredients

At the core of the FORMULATOR is a patented microfluidic chip that measures and dispenses discrete volumes of liquid. The chip has 96 outputs, each with its own microfluidic valve cluster. Each valve cluster has two micro-diaphragms (200 nL and 2.5 µL) that fill and dispense up to three times per second. By combining multiple dispenses of each micro-diaphragm, the FORMULATOR can dispense any volume down to 200 nL.

The FORMULATOR's positive displacement micro-diaphragms handle viscous and non-viscous liquids with ease and precision. Select from four viscosity settings (normal, medium, high, and very high) to define a reagent’s liquid class, and the system adjusts the diaphragm fill time to compensate.

Easily Create Screens with Up to 34 Ingredients

Easy Ingredient Switching

Adding ingredients is as easy as scanning the reagent barcode and inserting the bottle (with a specialized check-valve cap) into any open input on the top of the FORMULATOR. Bottle sensors tell the system where you positioned each reagent automatically, eliminating user error.

Models to Fit Your Budget and Workflow

The FORMULATOR comes in 3 different models based on the number of ingredients you need to create your crystallization screens (listed on the left). The systems support both 125 mL and 250 mL Nalgene bottles, as well as, 50 mL Falcon tubes. All of the models have the same physical size and offer an optional secondary wash input for other wash solutions.

FORMULATOR 10

- 9 inputs for either Nalgene bottles or 50 mL Falcon tubes

- 1 bulk pure water input for wash or to use as an ingredient

FORMULATOR 16

- 15 inputs for either Nalgene bottles or 50 mL Falcon tubes

- 1 bulk pure water input for wash or to use as an ingredient

FORMULATOR 34

- 30 inputs for 50 mL Falcon tubes

- 3 inputs for either Nalgene bottles or 50 mL Falcon tubes

- 1 bulk pure water input for wash or to use as an ingredient

Save on Protein + Reagents with MANTIS®

The FORMULATOR’s dead volume is as low as 5.1 mL. To lower the dead volume even further, the FORMULATOR can be integrated with the MANTIS, a precious ingredient dispenser, to achieve dead volumes of only 6 µL.

The MANTIS integrates seamlessly with the FORMULATOR, so adding the MANTIS to your existing workflow is simple. The system's software allows you to pick which bulk ingredients to dispense with the FORMULATOR and which valuable ingredients are better suited for the MANTIS.

MANTIS - Liquid Handler

- 6 µL dead volume conserves precious reagents

- Dispense range from 100 nL up provides ultimate flexibility for screen building and optimization

- Quick and easy setup

Size

FORMULATOR®

Width:

406 mm (16")

Depth:

434 mm (17")

Height without Bottle:

359 mm (14")

Height with Bottle:

482 mm (19")

Weight:

16 kg (35 lb)