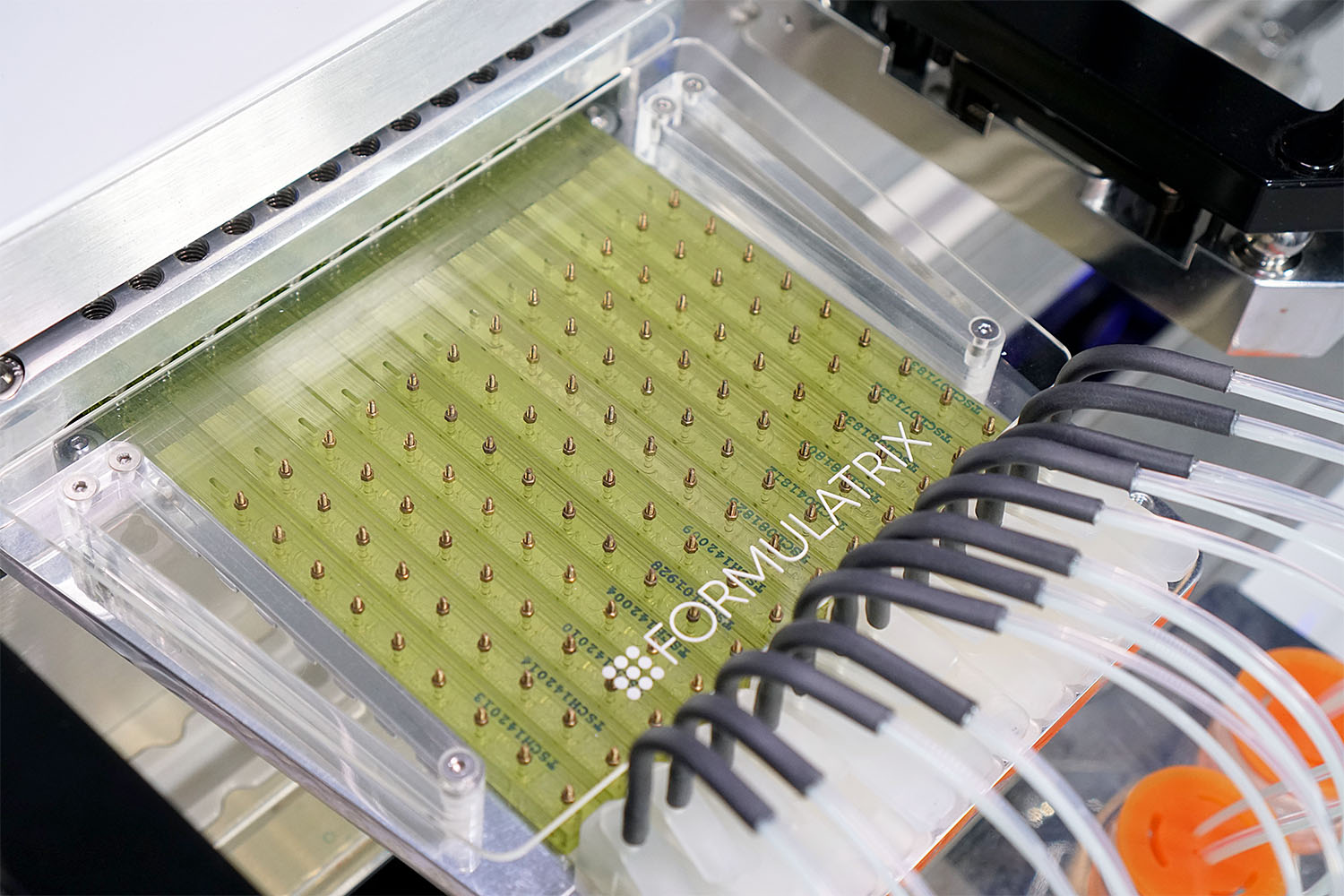

Using the TEMPEST® liquid handler from Formulatrix, and in collaboration with HighRes Biosolutions® for integration of the instrument with an existing automation platform, researchers at St. Jude Children’s Research Hospital were able to rapidly screen a focused compound library screening early cancer drug candidates in an AlphaLISA® assay. The success of this project was facilitated by a number of key TEMPEST® features, namely an in-built capacity to recirculate the AlphaLISA® beads, the ability to dispense multiple reagents from a single dispenser, and extremely low dead volumes.

Click here to access webinar recording.

At UCL, the Drug Discovery Group demonstrates that a hit confirmation run of 12,000 concentration response curves can be run with only 1.6 µL total reaction volumes when automated with the TEMPEST liquid handler resulting in a cost reduction of 26,000 GBP in detection reagent when compared to past liquid handling approaches.

The Mantis and Tempest are ideally suited for dispensing AlphaLISA® beads and reagents to maximize assay performance and minimize assay cost by reducing dead volume and enabling a simple and robust means to reduce reaction volumes without sacrificing the quality of experimental results.

The GeneMark lab is a relatively high throughput parentage lab based in Hamilton, New Zealand. The facility predominantly services the domestic bovine dairy industry and provides parentage determination from a single animal to a single parent all the way up to the entire crop of calves matched to both parents. Herd sizes average just over 500 animals and can be as large as several thousand.

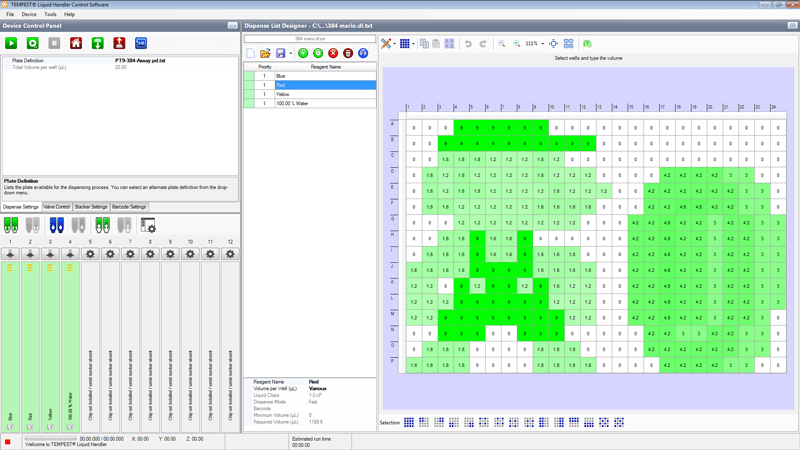

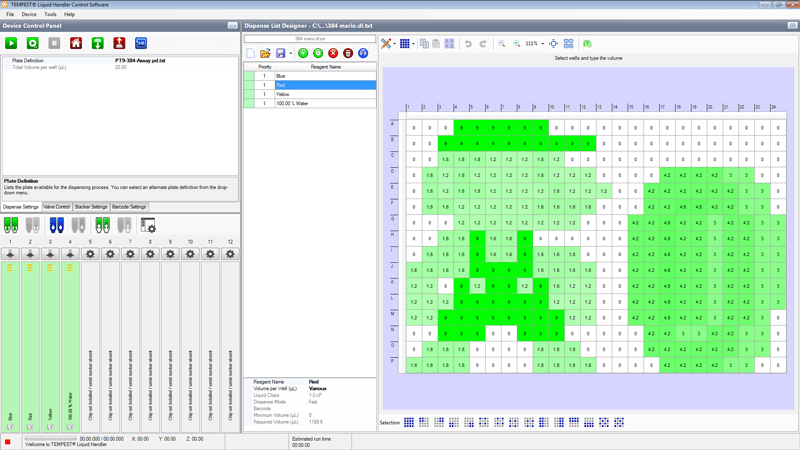

Efficient high-throughput screening is a complex system of samples, chemistry, automation, and data analysis. Traditional high-throughput systems utilize 6- to 1536-well plates to support the large number of experimental conditions required to produce reliable and statistically significant studies.

Here we present a unique system for the automated processing of both adherent and suspension cells by using Curiox Biosystems' DropArray™ Plates in combination with non-contact, low-volume automated liquid dispensing using the FORMULATRIX® TEMPEST® Liquid Handler

In support of its SelectScreen® Services business, global biotech company Life Technologies researched and tested automated liquid handlers to streamline the addition of adenosine triphosphate (ATP) to Z´-LYTE® 384 well assay plates. Rigorous testing proved that the FORMULATRIX TEMPES met all of Life Technologies’s strict reliability, accuracy and precision requirements. Today, the Tempest is a routine part of Life Technologies’s workflow.

Cell line generation has historically been considered a long and tedious, labor and materials intensive process. Monoclonality and robust clonal growth with high viability are desirable in cell line development, especially for generating monoclonal antibodies or protein therapeutics. In the pharmaceutical industry, scalability is also a necessity for bioprocess manufacturing. Decreasing the time and labor intensive method in the beginning of the process of plating single cells to insure monoclonality can be achieved together with the FORMULATRIX TEMPEST and Celigo imaging cytometer.