Volume Range

Min: 0.2 µL

Max: ∞

Technology

Micro-Diaphragm Pumps

+ Continuous Flow

Precision

CV <3%

@ 0.2 µL

Flexible and Precise Reagent Dispensing

Tempest® is a non-contact, multipurpose dispenser. Enabling you to dispense as many as 12 different reagents simultaneously by utilizing 96 independently controlled outputs. Dispense any volume, of any reagent, into any well.

- High Throughput Screening (HTS)

- Assay Development and Design of Experiment (DoE)

- Enzyme-Linked Immunosorbent Assays (ELISA)

- Polymerase Chain-reaction (PCR) Workflows - Real-time and Digital

- Biochemical assay development and screening

- Cell Culture and Bead-Based Assays

- Next Generation Sequencing (NGS) - Library Preparation

Benefits:

Precise - Non-contact microdiaphragm technology uses positive displacement, ensuring high accuracy and precision across a broad range of reagent types, including cells and beads.

Low Dead-Volume - Non-recoverable dead volume as low as 48 μL per chip.

Flexible - Tempest supports all SBS plate types, can easily be integrated with other robotic automation, and has an optional plate stackers and barcode reader. For lower through-put needs, see our Mantis® liquid dispenser.

Fast - Dispense 200 nL to 96-well plate in just 3 seconds and 1 μL to 384-well plate in just 5 seconds.

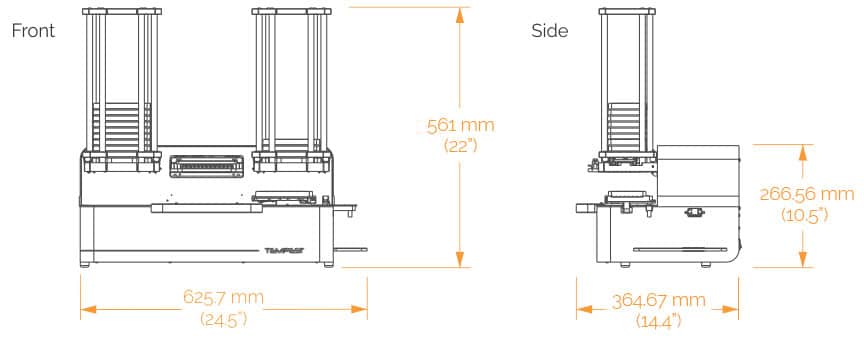

Biosafety Cabinet Compatible: With its compact dimensions (555 mm x 309.67 mm x 266.56 mm), the Tempest can be used in various biosafety cabinets to accommodate workflows that require this level of safety.

Overview of the TEMPEST®

State-of-the-art Dispensing Technology

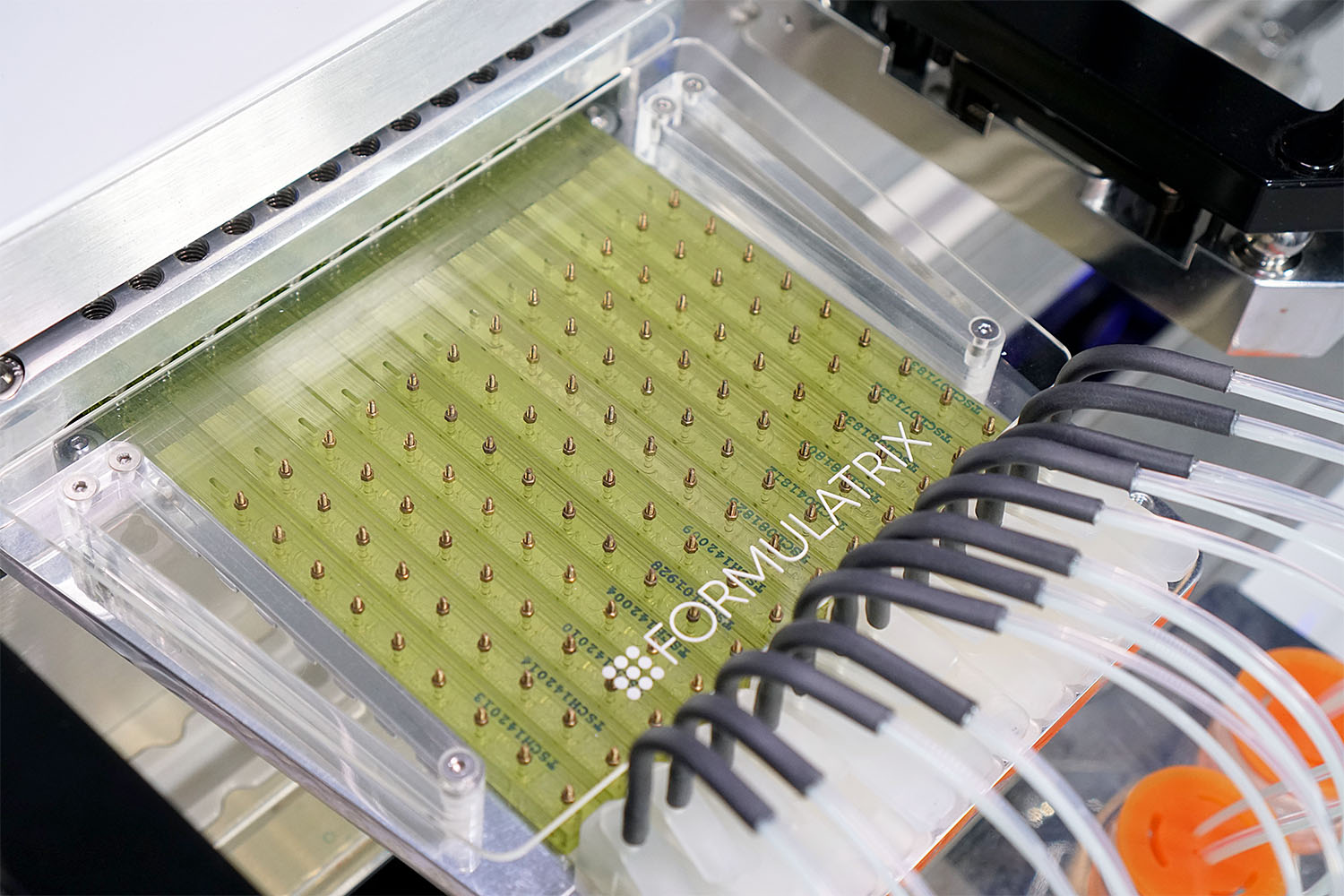

At the core of the Tempest is a microfluidic design that can dispense discrete volumes of liquid with incredible precision across a wide range of sample types and viscosities.

| Key Features | |

|---|---|

|

|

| Key Features | |

|---|---|

|

|

Unparalleled Ease and Excellence

The Tempest Liquid Dispenser utilizes patented microdiaphragm pump technology to allow researchers to maximize workflow efficiency from genomics to high-throughput screening workflows.

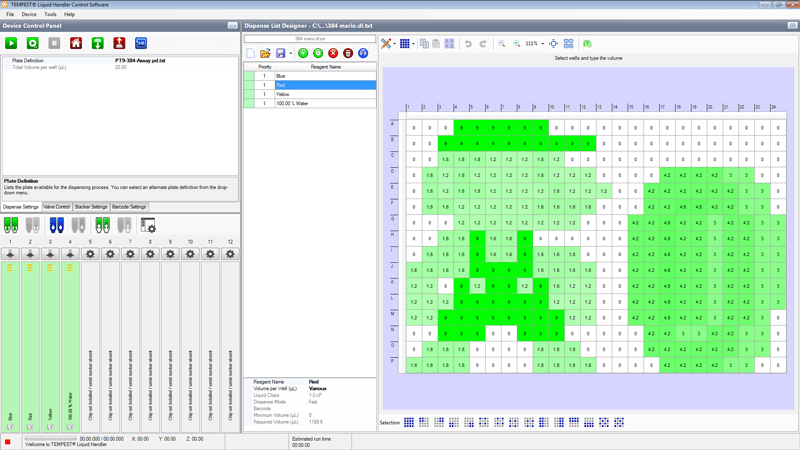

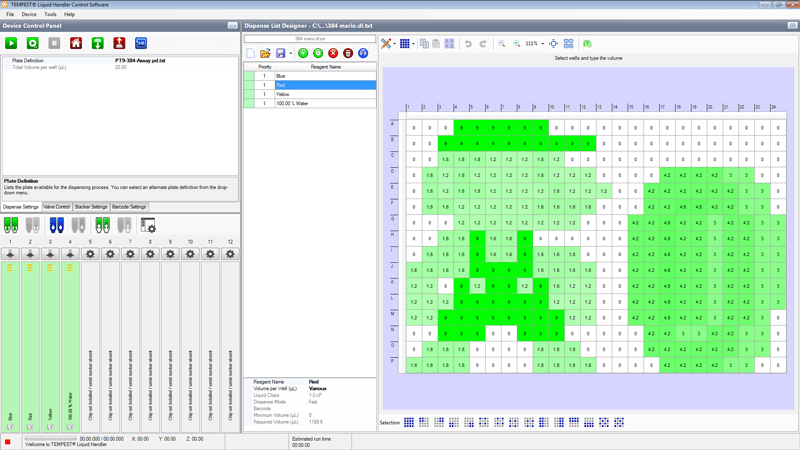

EASE OF USE: The Tempest software is extremely user-friendly allowing for easy experimental design. The standard gradient and backfill buttons make designing an experiment even easier and faster.

COST SAVINGS:

- Miniaturize assay design and reduce reagent usage

- Save precious reagents through low dead volumes

- Prevent failed experiments with clog-free dispensing technology

- Intuitive software interface and experimental design

- No Consumables. All components can be easily cleaned and re-used

“A fantastic instrument! We use the Tempest in our high throughput biochemical profiling service. The team now has an automated process for our reagent additions that requires certain concentrations to be added to a plate in a "cherry picking" type of methodology. What was once done by two individuals can now be done by one. The Tempest has worked great"

Chris Updike

Production Scientist

Save on Consumables with Tipless Dispensing

The Tempest uses a patented microdiaphragm pump that meters and dispenses discrete volumes of liquid. This valve cluster can fill and dispense as fast as 10 times per second. This proven technology is incredibly fast and precise.

When Speed Matters

Each 8-nozzled microfluidic chip dispenses reagents rapidly with minimal waste. Most tasks are completed in fewer than 40 seconds:

Typical Dispense Rates

- 200 nL to 96-well plate = 3 seconds

- 200 nL to 384-well plate = 6 seconds

- 200 nL to 1536-well plate = 11 seconds

- 5 μL to 96-well plate = 4 seconds

- 1 uL to 384-well plate = 5 seconds

- 10 μL to 384-well plate = 9 seconds

- 20 μL to 384-well plate = 13 seconds

The Tempest can be customized to fit your application and budget. The system offers plate stackers, a bar code scanner, independent vs general controls, as well as any combination of up to 12 high (1 μL and 5 μL) or low volume (200 nL and 1 μL) microfluidic chips.

“The Tempest allowed us to significantly scale up our biochemical HTS capabilities and has proven to be a reliable and accurate dispenser. We love the Smart Batch delayed dispensing feature as it greatly facilitates assay development work and converting end-point assays into kinetic assays, providing us more insightful data! The versatility of the Tempest in improving multiple workflows can't be overstated!"

Save Time on Your Dispenses with Continuous Flow

The Continuous Flow (CF) chip adds exceptionally fast plate filling to the Tempest system's trusted reliability and precise low-volume dispensing. The CF chip uses a pressurized reservoir to dispense a constant stream of liquid from all eight nozzle positions and can be installed alongside the standard diaphragm chips to provide a complete automation solution to your plate-filling needs.

- CV <3% across all eight nozzles when filling a 96-well plate

- Adjustable flow rates, capable of >400 µL per second

- Fill a 96-deep-well plate with 2 mL per well in under 2 minutes

“We use the Tempest in a fully automated set-up for medium throughput quantitative analysis. The CVs are great and due to the ultra-low dead volume, we could dramatically reduce reagent costings. Furthermore, the very innovative and robust dispensing technology lead to reduced maintenance compared to the dispenser we used before. We are also very happy with the support by FORMULATRIX personnel. We definitely recommend the Tempest!”

Johannes Fels

Principle Scientist

Easy-to-use Software

The software provides a straightforward, user-friendly way to design and execute even the most complex dispensing protocols. The control software offers an intuitive visual layout of both the plate design and the hardware setup, and provides tools to create gradient designs and backfills. Microsoft Excel integration allows you to manually edit well volumes for additional control.

Easy-to-use Software

The software provides a straightforward, user-friendly way to design and execute even the most complex dispensing protocols. The control software offers an intuitive visual layout of both the plate design and the hardware setup, and provides tools to create gradient designs and backfills. Microsoft Excel integration allows you to manually edit well volumes for additional control.

Common Applications

Miniaturize your cDNA synthesis and library preparation reactions, even with limited starting material.

Gentle and even distribution of suspension, adherent and 3D cell cultures.

Simplify the evolution from assay design to drug discovery.

Nucleic Acid Workflows

Automate your nucleic acid extraction, recombination, and synthesis while avoiding cross-contamination and ensuring precision with the tipless technology of the Mantis

“The [Tempest] is easy to configure and offers a high degree of versatility for liquid handling tasks. Having the stackers and a time delay option is immensely helpful for biochemical screens and other applications. The software for plate teaching and creating protocols is very simple to work with“