Jeremy Lambert1, Dan Lord1, Hanne Skov Pederson2, Per Nielsen2, Johannes Josef Fels2

1FORMULATRIX, Inc., 2Novo Nordisk, Inc.

Pharmacokinetic and Pharmacodynamic (PK/PD) studies play a critical role in the drug discovery and development process. The studies typically require characterization of drug and biomarker concentrations from large numbers of samples with high sensitivity and broad analytical range. The AlphaLISA® technology (PerkinElmer, Inc., Waltham, MA) is a homogeneous no-wash alternative to conventional solid-phase ELISA assays that can be applied to biomarker detection in plasma and serum samples.

The AlphaLISA workflow has been demonstrated to provide lower limits of detection, improved assay precision and broader dynamic range compared with conventional ELISA while allowing for a 5-fold reduction in sample volume for measurement of insulin in plasma samples. The technology has been applied in an automated process supporting high-throughput bioanalysis with a capacity in excess of 10,000 data points in 6 hours.

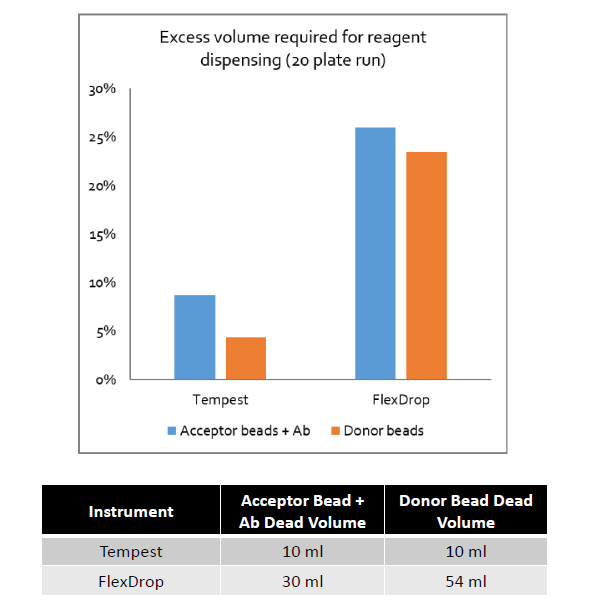

An integrated robotic workstation was designed to process up to 25 384-well plates in a 6- hour shift. In order to meet the required assay flexibility, the initial system design utilized two FlexDrop instruments for dispensing the AlphaLISA reagents. While this system design was capable of delivering the required throughput, the FlexDrop dispensers consumed up to 50 mL of reagents during the priming steps resulting in a significant increase in the reagent cost per plate.

Figure 4. Comparison of reagent utilization between TEMPEST® and FlexDrop instruments for automated AlphaLISA® (20 plate run).

The microfluidic diaphragm pump technology utilized in the TEMPEST instrument enabled a 3-5 fold reduction in priming volume of the AlphaLISA reagents while maintaining assay performance and reproducibility required for PK/PD studies.

In addition, the ability of the TEMPEST to dispense up to 12 reagents from 96 nozzles allows for a single Tempest instrument to replace two FlexDrop instruments, reducing the complexity of the system hardware. Finally, the increased capacity of the Tempest enables the option to run up to 8 different assays compared with only 6 assays with the alternative dispensing instruments.