Liquid handling in laboratory workflows refers to the process of transferring, dispensing, and manipulating liquids, typically at micro- or nanoliter volumes.

Liquid handling solutions range from manual to fully automated systems, each with its own advantages. When choosing between the systems, it is important to consider two key factors:

- The level of throughput required

- The level of accuracy and precision to generate statistically reliable data

Manual Liquid Handling

Hand-held pipettes is the conventional approach for lab protocols, involving a few liquid handling steps. However, user-to-user variability and liquid properties significantly compromise the accuracy and reproducibility of results. Additionally, it is inherently constrained by its inability to handle sub-microliter volumes and achieve high throughput. Collectively, these limitations make manual liquid handling unsuitable for workflows involving low volumes, complex liquid transfers, and high throughput.

Automated Liquid Handling

Automated liquid handling (ALH) addresses the reproducibility and throughput challenges associated with manual liquid handling by replacing the user and automating the process. The integrated control software enables users to define variables such as volumes, liquid properties, and handling parameters, ensuring consistent results. Thus, ALH systems efficiently execute complex workflows, enhancing the throughput, and promoting an ergonomic work environment by reducing the risk of repetitive stress injuries (RSIs). Sophisticated dispensing technologies used in ALH enable the precise transfer of even nanoliter volumes, facilitating assay miniaturization and reducing operating costs.

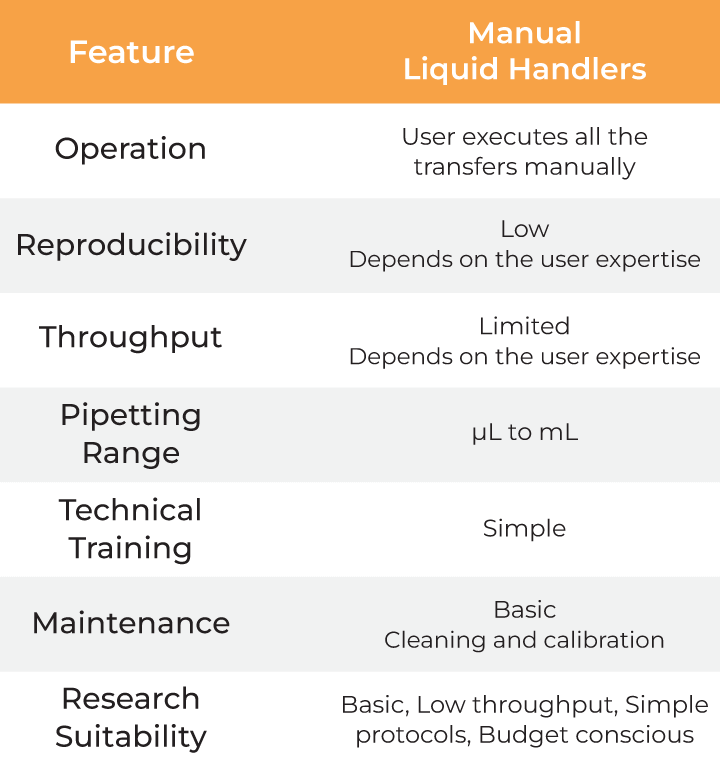

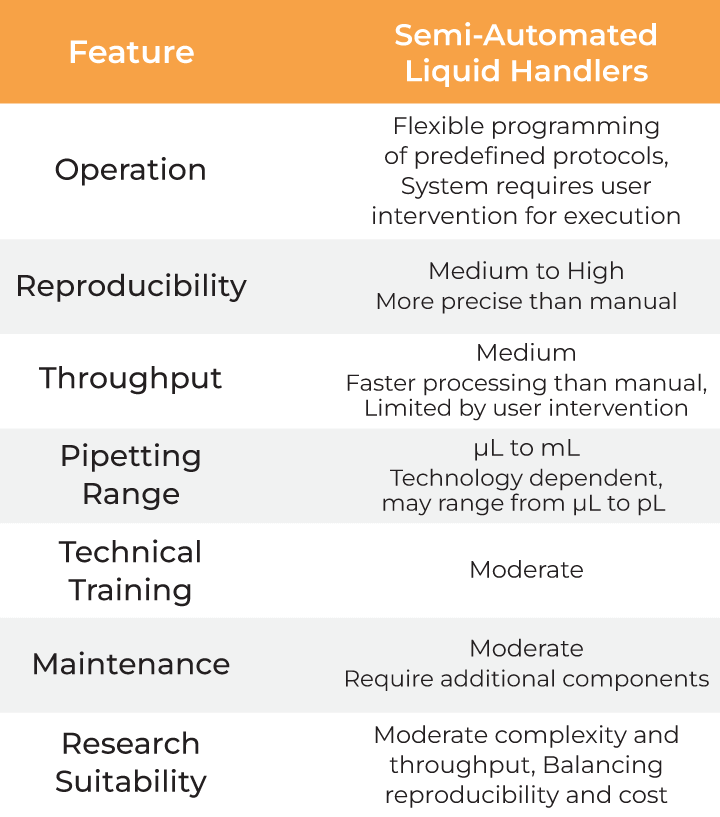

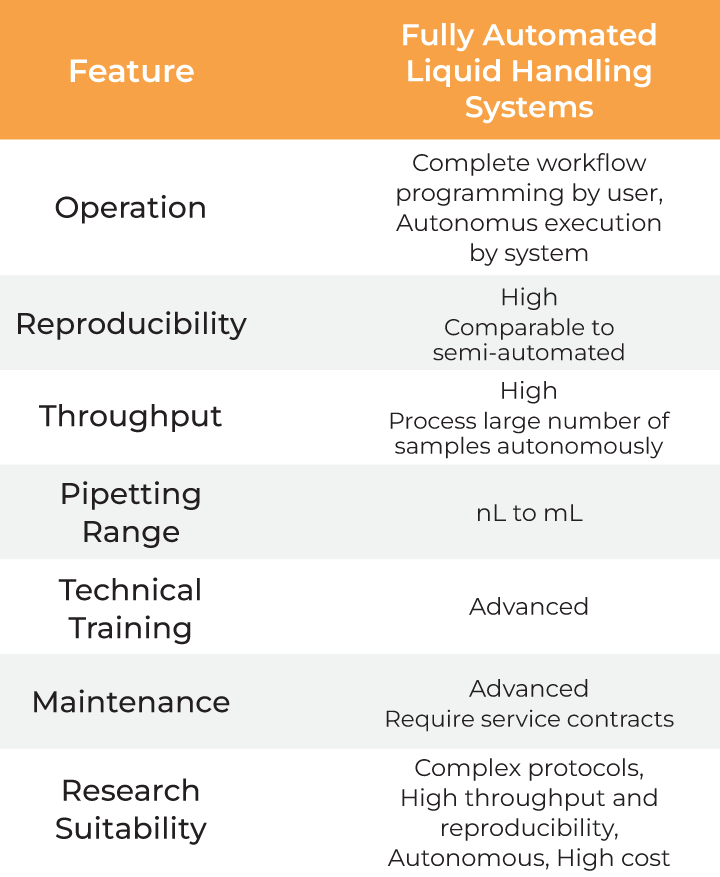

ALH can be classified into semi- and fully automated systems based on customization flexibility and throughput capabilities. The table below highlights the distinct features of different levels of liquid handling:

| Feature | Manual Liquid Handlers | Semi-Automated Liquid Handlers | Fully Automated Liquid Handling Systems |

|---|---|---|---|

| Operation | User executes all the transfers manually | Flexible programming of predefined protocols, System requires user intervention for execution | Complete workflow programming by user, Autonomous execution by system |

| Reproducibility | Low

Depends on the user expertise | Medium to High

More precise than manual | High

Comparable to semi-automated |

| Throughput | Limited Depends on the user expertise | Medium Faster processing than manual, Limited by user intervention | High

Process large number of samples autonomously |

| Pipetting Range | µL to mL | nL to mL

Technology dependent, may range from µL to pL | nL to mL |

| Technical Training | Simple | Moderate | Advanced |

| Maintenance | Basic

Cleaning and calibration | Moderate Require additional components | Advanced Require service contracts |

| Research Suitability | Basic, Low throughput, Simple protocols, Budget conscious | Moderate complexity and throughput, Balancing reproducibility and cost | Complex protocols, High throughput and reproducibility, Autonomous, High cost |

ALH Systems

Pipettors and dispensers are the two systems within ALH, each with its own distinct features.

Automated Pipettors

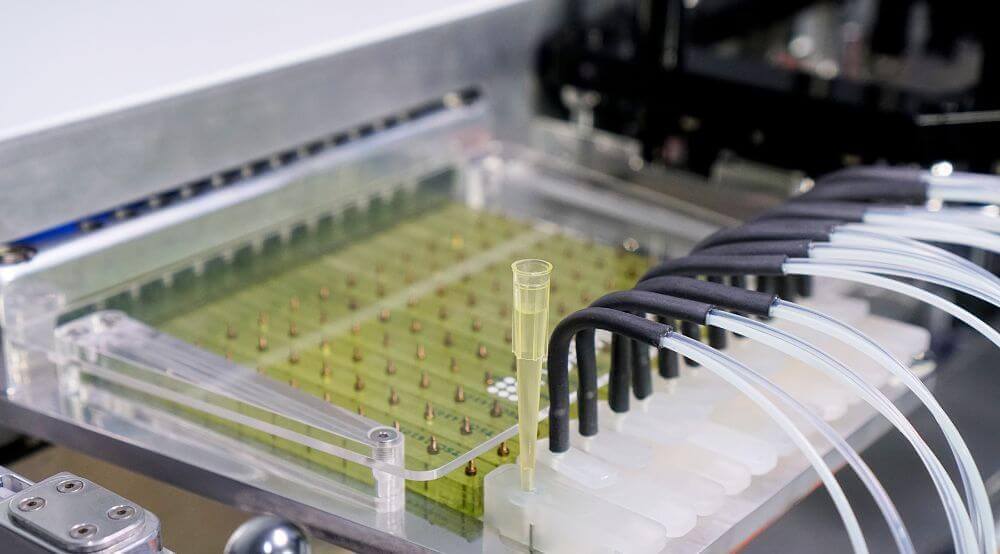

Pipettors are instruments that aspirate and dispense liquids through the same tip. They automate multiple-sample pipetting workflows, including simple transfers, mixing, serial dilution, and plate reformatting. Although pipettors can broadcast the liquids, they carry the inherent risk of cross-contamination, limited volume range, and high operating costs.

Automated Dispensers

In contrast, liquid dispensers are designed solely for dispensing liquids from dedicated reservoirs. They are the preferred choice for high throughput workflows involving bulk dispensing and concentration/volume normalization. Dispensers often utilize non-contact liquid dispensing, which provides a broad volume range, high speed, and precise volume transfers without the risk of cross-contamination. While they mitigate higher ongoing consumable costs, dispensers require regular maintenance to ensure optimal performance.

Technologies in ALH

Conventionally, automated pipettors are based on established air- or positive- displacement principles. However, specialized technologies like microdiaphragm pumps, piezoelectric, and acoustic droplet ejection are also employed for gentle non-contact dispensing from mL to sub-nL range.

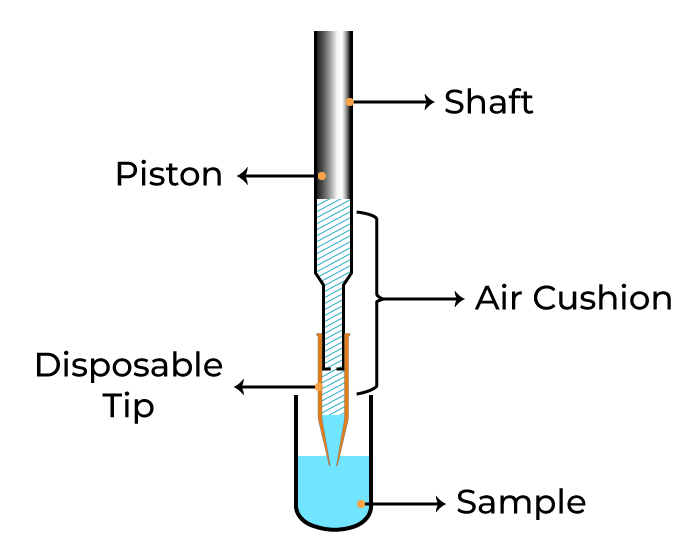

Air Displacement Technology

Air displacement functions through an air cushion: the positive or negative pressure generated by the movement of the piston inside the shaft transfers the liquids. Despite its wide implementation, air displacement can introduce variability, especially at sub-microliter volumes, due to the compressible nature of air.

It also poses the risk of carryover contamination from aerosols entering the air channel, particularly when working with volatile liquids. Moreover, this technology is less suitable for viscous liquids, as specific liquid classes must be defined to accommodate different viscosities.

Air Displacement Technology

Positive Displacement Technology

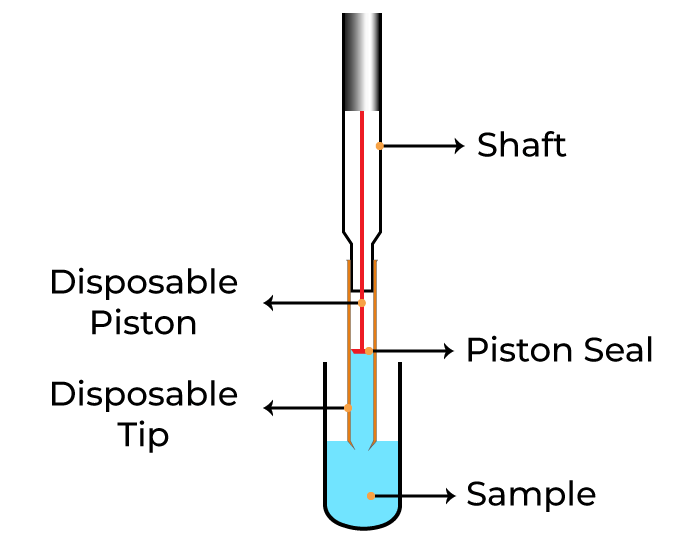

Unlike air displacement, positive displacement eliminates the air gap as the piston directly contacts the liquid, ensuring precise transfer even at sub-microliter volumes, regardless of the liquid properties. While traditionally reliant on reusable syringes, sterile and disposable tips address the sterility concerns of positive displacement for sensitive workflows.

The F.A.S.T. and FLO i8 PD liquid handlers by Formulatrix utilizes positive displacement disposable tips with axially-sealed plungers, further eliminating contamination risks.

Positive Displacement Technology

Microdiaphragm Pumps Technology

Microdiaphragm pumps use a flexible diaphragm that is activated by pneumatic means and rhythmically pulsates to convey precise volumes. They offer broad liquid class compatibility and gentleness. When combined with non-contact dispensing, this technology further mitigates the risk of contamination, making it a comprehensive solution for precise and sterile liquid handling. Our Mantis and Tempest liquid dispensers utilize microdiaphragm chips, achieving high precision and fast speeds.

Formulatrix Automated Liquid Handling

Formulatrix ALH portfolio includes the liquid dispensers Mantis and Tempest alongside the liquid handlers F.A.S.T. and Flo i8. Our systems streamline workflows and exhibit adaptability across a multitude of applications.

Mantis - Precise Liquid Dispenser

The Mantis is a programmable, low dead volume, non-contact liquid dispenser that can reliably dispense a variety of solutions including those containing beads, cells, proteins, enzymes, probes, and master mixes.

- Miniaturize reactions, scale up throughput, save on reagents, and remove pipette tip cost

- Dispense volumes down to 100 nL at CV < 2%

- Verify every dispense run with the Quality Control Droplet Detection Station

- Define labware in seconds with the new Interactive Labware Teaching module

Tempest - Bulk Liquid Dispenser

The Tempest is a non-contact, bulk reagent dispenser that utilizes 96 individually controlled nozzles to dispense any volume of up to 12 different reagents into any well.

- Ensure high accuracy and precision across a broad range of reagents, including cells and beads, using the non-contact microdiaphragm technology

- Deliver up to 12 reagents through 96 individually controlled nozzles

- Minimize reagent loss with non-recoverable dead volume as low as 48 μL per chip

- Rapidly dispense down to 200 nL (CV <5%) with no upper limit

F.A.S.T. - Liquid Handler

The F.A.S.T. (Flow Axial Seal Tip) is a reliable and easy-to-use liquid handler designed to move any viscosity of liquid quickly with its one-of-a-kind 96-channel head based on positive displacement technology.

- Save time on liquid transfers with a unique 96-tip head

- Save on consumables by using your choice of 1, 8, 12, or 96 tips to transfer reagents between 96- and 384-well plates

- Perform cherry-picking, serial dilutions, and plate copies (broadcast, mother-daughter transfers) with ease

- Forget having to program liquid classes ever again; the positive displacement tips mitigate the effects of viscosity on accuracy

FLO i8 PD - Liquid Handler

- Easily design protocols with a user-friendly software

- Simplify tube or plate-based lab work using eight variable independent spanning channels and volume range of 0.2 to 1000 μL.

- Swiftly aliquot reagents into tubes or dispense directly into plates with NCD precision.

- Engineered to be liquid-class agnostic—ideal for volatile and highly viscous liquids

- Make your workflows hassle-free with liquid level detection and tracking, automatic labware sensing, and collision detection

Applications of Formulatrix ALH Portfolio

Formulatrix ALH products offer precision, high throughput, and miniaturization to streamline a diverse range of workflows such as:

Miniaturize your cDNA synthesis and library preparation reactions, even with limited starting material.

Gentle and even distribution of suspension, adherent, and 3D cell cultures.

Simplify the evolution from assay design to drug discovery.

Webinars

Learn how to automate and miniaturize assays in PCR, NGS, and other workflows, boosting data quality and throughput while reducing costs using the Mantis and the Tempest liquid dispensers.

Deliver precise volumes regardless of liquid properties, eliminating viscosity and surface tension concerns with the F.A.S.T., a 96-channel positive displacement liquid transfer system.

Optimize multifactorial experiments through seamless adoption of Design of Experiment (DoE) workflows enabled by a powerful combination of the Synthace software platform and the Tempest.

Application Notes

Contemporary researchers prefer automated liquid handling to minimize user errors, and the Mantis achieves exceptional precision (CVs under 2%) in liquid transfers.

Consistent cell plating and cell viability is imperative for reproducible screening. The Mantis is a precise, reliable, and robust solution for dispensing even the most sensitive primary neuronal cells.

Execute assay development and high throughput screens in miniaturized assay volumes using the Tempest Liquid Dispenser, driving down the cost by 60% while enhancing data quality.

AlphaLISA is well-suited for high throughput analysis but constrained by high costs. The Tempest significantly reduces reagent consumption while increasing flexibility and throughput.